Flat guide vs. linear guideway on MTE milling machines

Discover the world of guidance technologies in the mechanical engineering industry with us: Flat guideways vs. linear guideways – which system offers the optimal combination of all properties for your milling machine?Flat guide on MTE milling machines

We began building our first machines 30 years ago and opted for proven flat guide technology.

Design

A flat guide consists of two main parts: a flat guide rail and a carriage that slides on it. The guide rail is usually made of hardened steel and precision machined. This ensures a smooth and straight surface.

Freedom of movement

Flat guides enable linear movements in one direction. Precise, straight movements are crucial for workpiece machining, especially in milling machines.

Stability and precision

The large contact surface of the flat guide rail ensures high stability and accuracy of movement. This minimises the likelihood of deviations or vibrations during the milling process.

Friction and wear

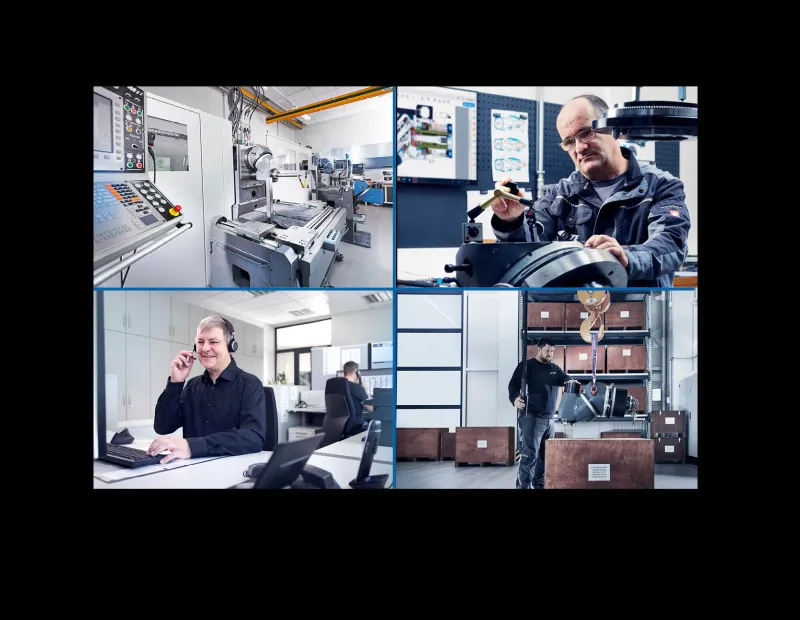

Flat guides can be designed as sliding or rolling guides. Sliding guides have higher friction but offer a very rigid connection. We use sliding flat guides in our bed type milling machines. These flat guides are coated with a hard plastic and are permanently and automatically lubricated. Manufacture of a flat guide Solid castings form the basis of every machine we build. Unlike steel welded constructions, this results in high stability and very good vibration behaviour. After the casting process, we pre-mill our assemblies on our own MTE milling machines. The assemblies are then stored in the warehouse to allow any tension in the workpiece to escape. We then mill and grind the assemblies to size on a surface grinding machine. The moving guide surface is coated with plastic to minimise wear. Finally, true artists are at work: they scrape the guides of our flat-guided milling machines by hand – a job that requires a great deal of expertise. We only employ employees with many years of experience for this task.

Linear guideways in MTE milling machines

In addition to stability and precision, new factors came to the fore in the construction of milling machines. The machines had to become increasingly dynamic in order to speed up the machining process and achieve higher tool feed rates. With the construction of linearly guided milling machines, we have also taken up and implemented these market requirements. Construction In milling machines, linear guideways were developed to enable precise linear movements of the machine tables and machine slides. Linear guideways consist of precisely machined guide rails and carriages or slides with bearings that either slide or roll. Freedom of movement Linear guideways enable movements in one or more axes. In our MTE milling machines, they are used for the X, Y and Z axes to move the machine table/machine tower and the milling head. Stability and precision

Linear guideways offer high stability and precision. They minimise deviations and vibrations during the milling process and thus contribute to high machining accuracy. Production of a linear guideway As with our flat guided machines, a stable cast construction forms the basis. First, we mill the bearing surface. Many machine manufacturers would install the guides at this point. However, we also grind the contact and reference surfaces on our linear-guided milling machines to achieve maximum accuracy and stability. This improves the load distribution and increases stability and accuracy.

Conclusion: Specific requirements and type of machining are decisive

Linear guideways offer higher precision and can achieve faster movements. Flat guides offer higher stability and damping, but require more maintenance.

Linear guideway or flat guide? The right decision depends on the specific requirements for the milling machine and the type of machining required.

Our bed type milling machines offer both types of guideways to build the perfect machine for every application. For our larger machines, such as floor type milling machines and fixed table travelling column milling machines, we rely exclusively on linear guideways.