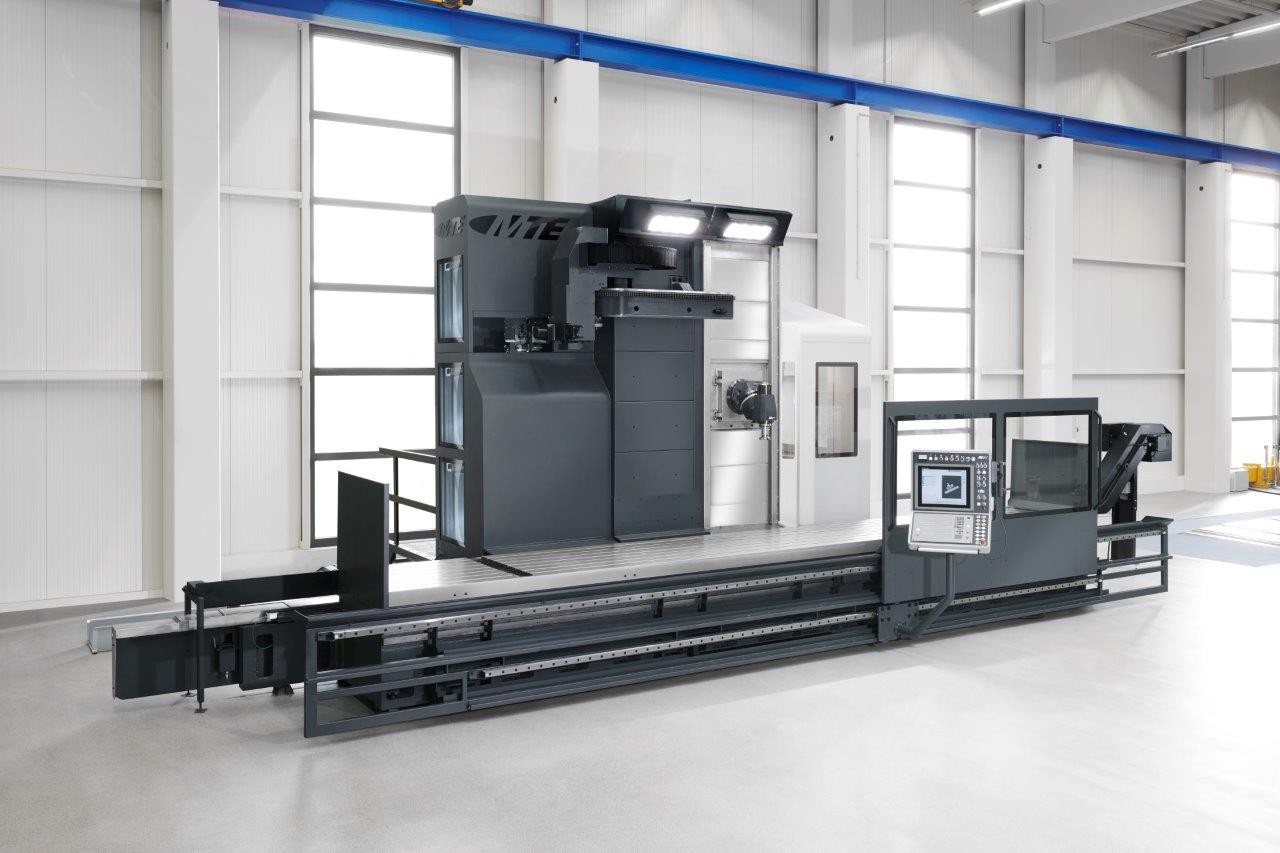

Fixed table travelling column milling machines

SB-M series

Travels

X: 3.500 - 20.500 mm

Y: 1.500 - 2.500 mm

Z: 1.000 - 1.600 mm

Adapted to your machine foundation – our new SB-M fixed table travelling column milling machine: Our MTE SB-M combines the decisive advantages of floor type milling machines and bed type milling machines. The fixed table, which can be mounted above the floor, ensures very high basic stability. At a height of 850 mm, workpieces can be handled extremely ergonomically and set up by your machine operator. With the latest drive and milling head technology in the oversized milling tower/slider, the SB-M delivers extreme milling performance.

Adapt the machine exactly to your requirements. Choose whether the control cabinet or cooling units are mounted on the milling tower or separately. Or whether the milling ram is positioned on the left or right side of the tower. Your machine operators will find familiar conditions and can continue with their established milling and drilling strategies. Replacing your old machine is (almost) child's play.

Adapt the machine exactly to your requirements. Choose whether the control cabinet or cooling units are mounted on the milling tower or separately. Or whether the milling ram is positioned on the left or right side of the tower. Your machine operators will find familiar conditions and can continue with their established milling and drilling strategies. Replacing your old machine is (almost) child's play.

- Heavily ribbed, vibration-damping cast iron construction of the entire machine

- INA linear guideways on all axes

- Highly dynamic digital drives (25,000 mm/min)

- 43 kW main spindle motor

- Spacious and ergonomic operator platform

- Individually adapted and practical enclosure

- Interface compatibility

- Multitasking: milling and turning on one machine

| Verfahrwege | SB-M 5.000 | SB-M 6.000 | SB-M 7.000 | SB-M 8.000 | SB-M 9.000 | SB-M 10.000 | SB-M 11.000 | SB-M 12.000 | |

|---|---|---|---|---|---|---|---|---|---|

| X-Achse längs | mm | 3.500 | 4.500 | 5.500 | 6.500 | 7.500 | 8.500 | 9.500 | 10.500 |

| Y-Achse vertikal | mm | 1.500 - 2.500 | 1.500 - 2.500 | 1.500 - 2.500 | 1.500 - 2.500 | 1.500 - 2.500 | 1.500 - 2.500 | 1.500 - 2.500 | 1.500 - 2.500 |

| Z-Achse horizontal | mm | 1.000 - 1.600 | 1.000 - 1.600 | 1.000 - 1.600 | 1.000 - 1.600 | 1.000 - 1.600 | 1.000 - 1.600 | 1.000 - 1.600 | 1.000 - 1.600 |

| Tisch | SB-M 5.000 | SB-M 6.000 | SB-M 7.000 | SB-M 8.000 | SB-M 9.000 | SB-M 10.000 | SB-M 11.000 | SB-M 12.000 | |

|---|---|---|---|---|---|---|---|---|---|

| Aufspannfläche (Option) | mm | 5.000 x 1.000 (1.100 - 1.500) | 6.000 x 1.000 (1.100 - 1.500) | 7.000 x 1.000 (1.100 - 1.500) | 8.000 x 1.000 (1.100 - 1.500) | 9.000 x 1.000 (1.100 - 1.500) | 10.000 x 1.000 (1.100 - 1.500) | 11.000 x 1.000 (1.100 - 1.500) | 12.000 x 1.000 (1.100 - 1.500) |

| Spindel | SB-M 5.000 | SB-M 6.000 | SB-M 7.000 | SB-M 8.000 | SB-M 9.000 | SB-M 10.000 | SB-M 11.000 | SB-M 12.000 | |

|---|---|---|---|---|---|---|---|---|---|

| Spindeldrehzahlbereiche | U/min. | 4.000 - 6.000 | 4.000 - 6.000 | 4.000 - 6.000 | 4.000 - 6.000 | 4.000 - 6.000 | 4.000 - 6.000 | 4.000 - 6.000 | 4.000 - 6.000 |

| Leistung | kW | 43 | 43 | 43 | 43 | 43 | 43 | 43 | 43 |

| Drehmoment bei 43kW 4000/6000 U/min. | Nm | 920 (S1) - 1.290 (S6) | 920 (S1) - 1.290 (S6) | 920 (S1) - 1.290 (S6) | 920 (S1) - 1.290 (S6) | 920 (S1) - 1.290 (S6) | 920 (S1) - 1.290 (S6) | 920 (S1) - 1.290 (S6) | 920 (S1) - 1.290 (S6) |

| Autom. Schwenkkopf: diagonal | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | |

| Autom. Schwenkkopf: orthogonal | 1°×1° | 1°×1° | 1°×1° | 1°×1° | 1°×1° | 1°×1° | 1°×1° | 1°×1° |

| Vorschübe | SB-M 5.000 | SB-M 6.000 | SB-M 7.000 | SB-M 8.000 | SB-M 9.000 | SB-M 10.000 | SB-M 11.000 | SB-M 12.000 | |

|---|---|---|---|---|---|---|---|---|---|

| Eilgang (X/Y/Z) max. | mm | 25.000 | 25.000 | 25.000 | 25.000 | 25.000 | 25.000 | 25.000 | 25.000 |

| Weitere Daten | SB-M 5.000 | SB-M 6.000 | SB-M 7.000 | SB-M 8.000 | SB-M 9.000 | SB-M 10.000 | SB-M 11.000 | SB-M 12.000 | |

|---|---|---|---|---|---|---|---|---|---|

| Werkzeugwechsler Random | Plätze | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

| Werkzeugwechsler H/V-Kette | Plätze | 40 / 60 / 80/ 100 / 120 | 40 / 60 / 80/ 100 / 120 | 40 / 60 / 80/ 100 / 120 | 40 / 60 / 80/ 100 / 120 | 40 / 60 / 80/ 100 / 120 | 40 / 60 / 80/ 100 / 120 | 40 / 60 / 80/ 100 / 120 | 40 / 60 / 80/ 100 / 120 |

| IKZ und Außenkühlung Luft und/oder Wasser | bar | 20-70 | 20-70 | 20-70 | 20-70 | 20-70 | 20-70 | 20-70 | 20-70 |

| CNC Steuerung | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens |

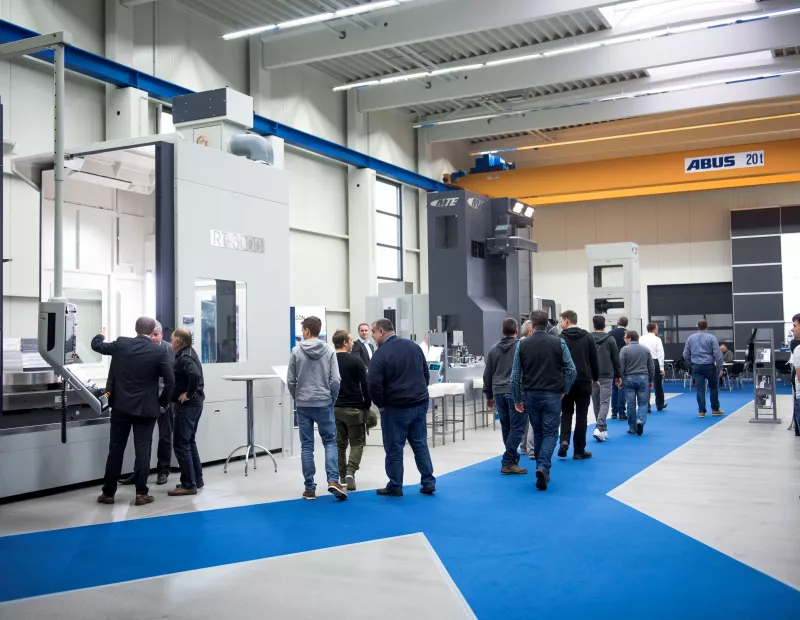

Highlights der Maschine

You can find all the highlights on the machine card.

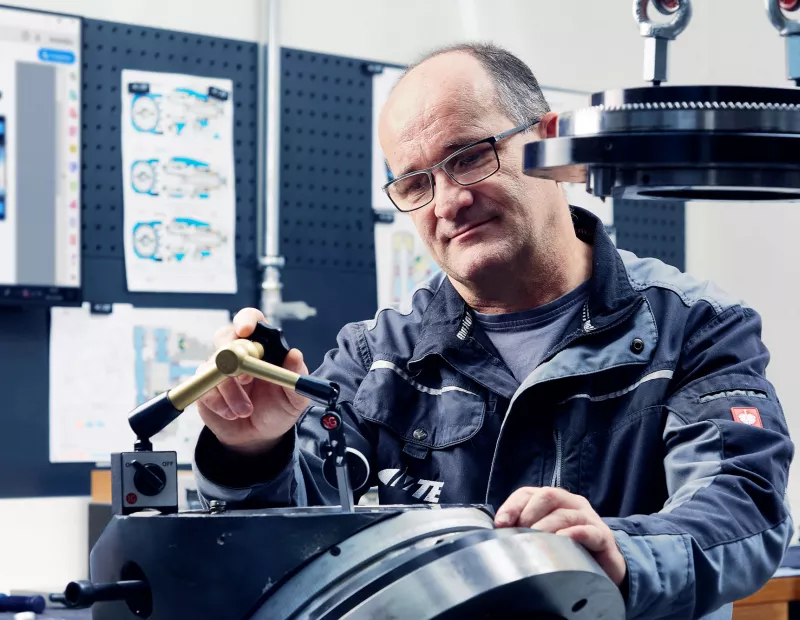

accuracy of fit

- Use of new MTE rigid bed on your existing rigid bed foundation

- Precise fit on old foundations for almost all makes

- Old foundations can be used individually thanks to modular MTE rigid bed design

accuracy

- More stable cast construction of the entire machine calculated using FEM

- High accuracy thanks to backlash-free INA linear guides in all axes

- Ground contact surfaces for all guideways, measuring systems, etc.

- Maximum precision in the milling slide axis thanks to preload on the INA guides

FEM

- Designed according to FEM

- Greater rigidity and damping

- Insensitive to minor collisions and tool breakage

- Vibration-free without electromechanical compensation systems

Environment

- Avoiding unnecessary consumption of resources

- Reducing environmentally harmful measures

- Intelligent, needs-based switch cabinet and hydraulic solutions