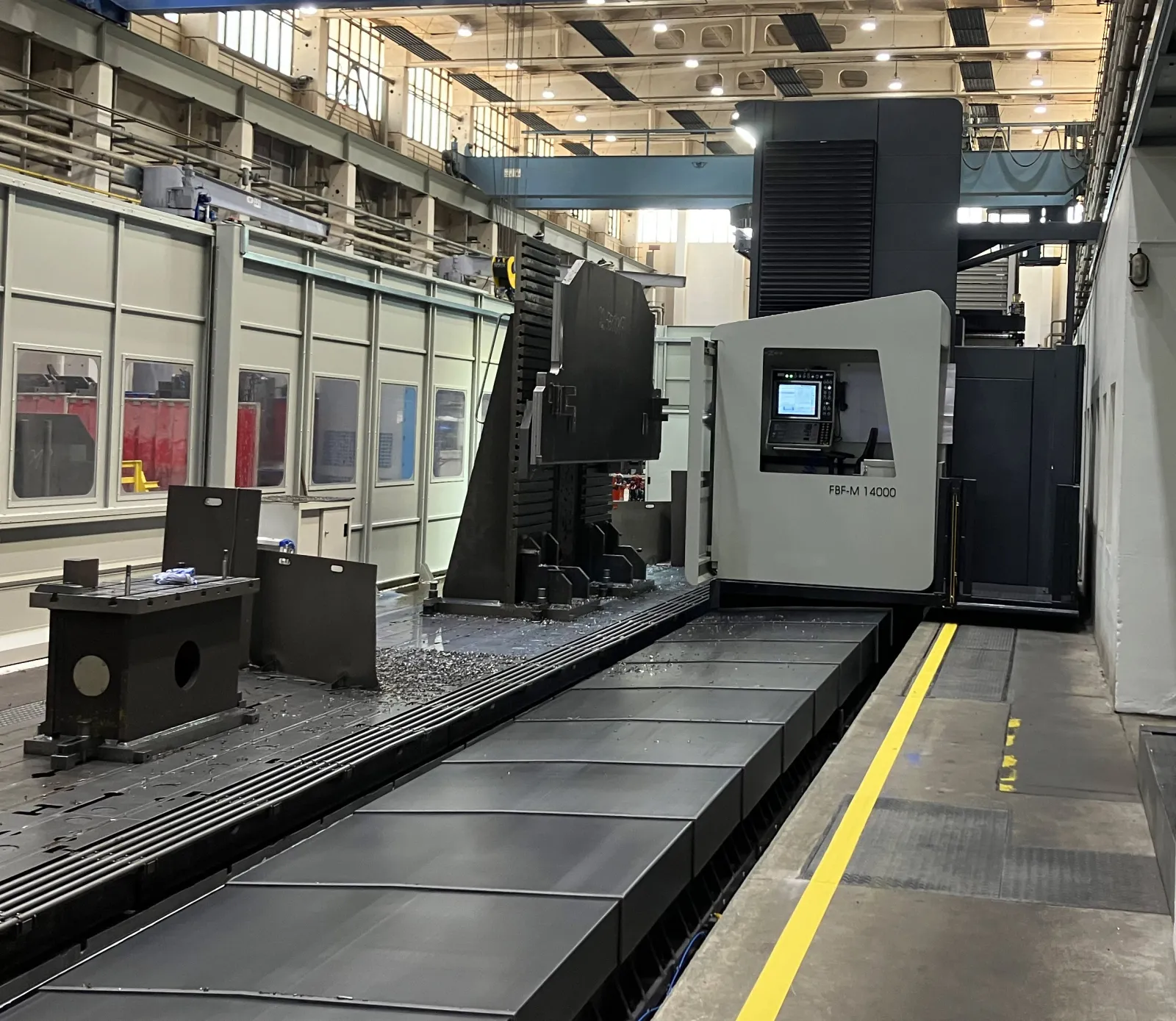

Customised large milling machines from MTE: Tailor-made machine construction

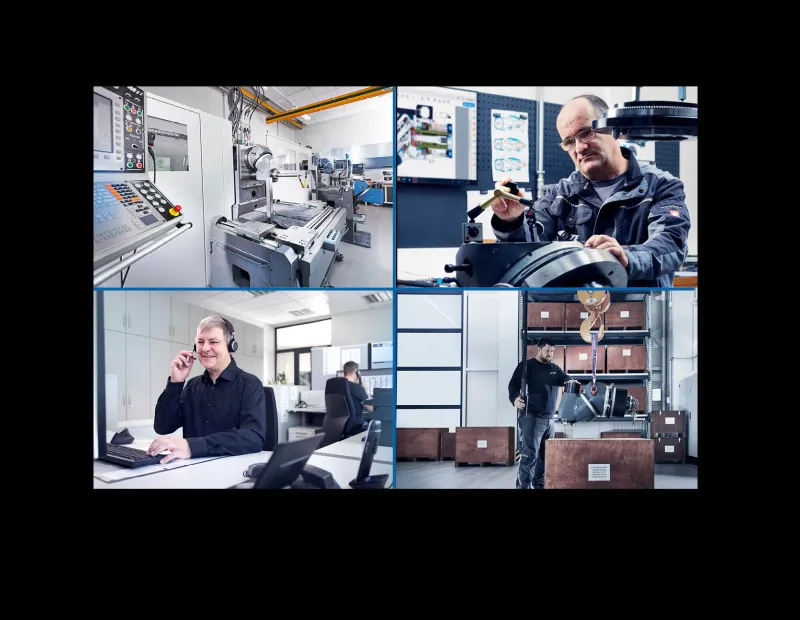

In a manufacturing world increasingly characterised by complexity, individual requirements and spatial challenges, it is no longer enough to offer standard solutions.At MTE Germany, we have therefore consistently focused on developing highly complex large milling machines that are tailor-made to the specific needs of our customers.

No two machines are alike

In the past, it was not unusual for identical machines to be built multiple times. Today, this is the exception rather than the rule. Almost every machine we deliver is unique – configured and designed based on the individual requirements of our customers' production processes. We draw on an extensive modular system that opens up a wide range of configuration options.

Maximum flexibility for installation situations

Creativity is often required, especially when it comes to the space available in our customers' workshops. In many cases, only limited space is available – or the new machine even has to be built on an existing foundation. This is precisely where our strength lies: thanks to our flexible design and experience, we can adapt machines precisely to the spatial conditions on site. Customisable enclosures and cabins We also offer maximum customisation when it comes to enclosures. Whether machines with a full cabin, open top, side doors or completely enclosed – we build the machine to suit your production requirements. It's not just about milling for us, it's about your efficiency, ergonomics and safety.

Ergonomic operation – flexible control

Our machines are intuitive to operate – exactly where you need them. We offer, among other things:

> Swivel control panels that can be moved from front to back

> Machines with two control units for greater flexibility

> Separate control units on the tool magazine, especially for tool management

Whether Heidenhain or Siemens control – we adapt to your operating concept.

Variety of milling heads and tool magazines

Our machines can be configured with a variety of milling heads:

> Automatically changeable angle milling heads

> Drill spindles

> Pick-up stations for changing between different heads

Depending on your requirements, we can supply machines with:

> Trommel tool changers

> Chain type magazin

> Tool arenas for particularly extensive tooling

This ensures that even complex machining tasks can be completed in an automated process without retooling.

Rotary and carousel turning tables for maximum flexibility

For complex turning operations and combined milling/turning processes, we offer a wide range of NC-controlled rotary tables and carousel turning tables:

> Use as a 4th axis or full-fledged carousel table

> Integration of zero-point clamping systems (e.g. Schunk, SMW Autoblok)

> Optional with pallet changing system

> Options for simultaneous turning, turning tool holders,

This enables us to achieve maximum efficiency in the production of rotationally symmetrical components, heavy castings or complex housings with turning and milling operations in a single clamping.

Dreh- und Karusselldrehtische für maximale Flexibilität

Für komplexe Drehbearbeitungen und kombinierte Fräs-/Drehprozesse bieten wir eine breite Auswahl an NC-gesteuerten Drehtischen und Karusselldrehtischen:

> Einsatz als 4. Achse oder vollwertiger Karusselltisch

> Integration von Nullpunktspannsystemen (z. B. Schunk, SMW Autoblok)

> Optional mit Palettenwechselsystem

> Optionen für simultanes Drehen, Drehstahlhalter,

Damit schaffen wir höchste Effizienz bei der Fertigung von rotationssymmetrischen Bauteilen, schweren Gussteilen oder komplexen Gehäusen mit Dreh- und Fräsbearbeitung in einer Aufspannung.

Fit für die Zukunft: Automatisierung mit Palettenwechslern

Ein weiteres Feld, das für viele Kunden an Bedeutung gewinnt, ist die Automatisierung. Wir bieten Ihnen dafür integrierte Palettenwechselsysteme, die Stillstandzeiten reduzieren und die Produktivität Ihrer Maschine auf ein neues Niveau heben. Die Maschinen von MTE sind automatisierungsfähig und können perfekt in Ihre Fertigungsstrategie eingebettet werden – egal, ob Sie heute schon automatisieren oder erst in Zukunft planen.

Fit for the future: automation with pallet changers

Another area that is becoming increasingly important for many customers is automation. We offer integrated pallet changing systems that reduce downtime and take the productivity of your machine to a new level. MTE machines are automation-ready and can be perfectly integrated into your manufacturing strategy – regardless of whether you are already automated or only planning to automate in the future. Conclusion: We build your machine – not just any machine. At MTE Milling Machines, you don't get an off-the-shelf machine. You get a solution that is precisely tailored to your production reality, your spatial requirements and your technological requirements. With modular technology, a high level of innovation and a clear focus on customer proximity and flexibility.

If you too are facing the challenge of integrating a large milling machine into an existing environment or need a customised solution, we are ready to help.

Your requirements. Our machine. Tailor-made.