training courses

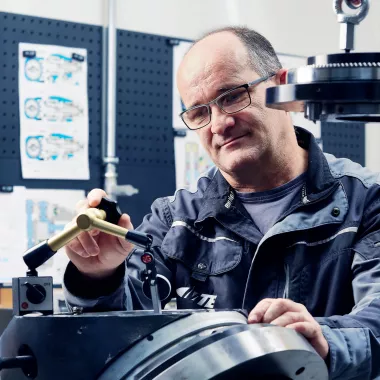

For better performance: Our training courses.We are happy to share our knowledge in training courses. This ensures that your MTE can perform properly. Benefit directly at your premises or attend training at our premises!Would you like to attend a training course? Or would you like more information?

Arrange trainingTraining courses

Training courses are certainly not always necessary – but they can never do any harm. That is why we offer individually tailored training courses for delivery, installation and commissioning. This enables your operating personnel to work better and more safely.

We would be happy to conduct this training at your premises. If you prefer, your employees can also be trained on the demonstration machines at our facility in Montabaur.

Find the training course that suits you!

Training package for maintenance mechanics

Key data:

- Number of participants: max. 4 people

- Training duration: 3 days (at our training centre or at your premises)

- Target group: Maintenance personnel, mechanics, possibly operators

- Cost: on request

Training content:

- Structure of documentation

- Structure of pneumatic diagrams

- Preventive maintenance in accordance with MTE documentation

- Removing and installing the milling head

- Aligning the milling head

- Replacing the drive belt

- Lubrication of milling head / axes

- Tool changer

- Hydraulic system

- Pneumatics

- Coolant system lifting tank/lifting pump

- Chip conveyor

- Geometry

Training package for electronics maintenance engineers

Key data:

- Number of participants: max. 4 people

- Training duration: 3 days (at our training centre or at your premises)

- Target group: Electronics maintenance personnel

- Cost: on request

Training content:

- Structure of documentation

- Structure of electrical circuit diagrams

- Preventive maintenance in accordance with MTE documentation

- Structure of the control system

- Measuring system

- Milling head swiveling process

- Tool changer

- Switch cabinet construction

- Data backup

- Replacement of assemblies

- Cables and plug connections

- PLC overview and troubleshooting

- HSCI bus system troubleshooting

Basic operator training

Key data:

- Number of participants: max. 4 people

- Training duration: 5 days (at our training centre or at your premises)

- Target group: machine operators

- Cost: on request

Training content:

- Control system structure

- Programming basics

- Creating programmes

- Reading/writing CNC programmes

- Coordinate system, machine zero point, reference point

- Tool management, loading/unloading of tool magazine

- MTE cycles

- Workpiece zero point (zero point shift)

- Working in the tilted plane

Operator advanced training

Key data:

- Number of participants: max. 4 people

- Training duration: 3 days (at our training centre or at your premises)

- Target group: machine operators

- Cost: on request

Training content:

- Machine structure and operating elements/special features

- Coordinate system, machine zero point, reference point

- Technical data of the machine

- Tool management, loading/unloading the tool magazine

- Tool change, emergency operation of the tool changer

- Reading/writing CNC programs

- MTE cycles

- Workpiece zero point (zero point shift)

- Working in the swivelled plane

- Probe/measuring device

- Automatic mode: program test, program interruption, block search

- Optional machine functions, e.g. pendulum operation, rotary table, turning device

- Documentation structure

- Basic maintenance for the user

Training course: Milling head maintenance and bearing replacement

Key data:

- Number of participants: max. 4 people

- Training duration: 5 days (at our training centre or at your premises)

- Target group: machine operators

- Cost: on request

Training content:

- Milling head structure

- Checking the bearing play of the front spindle bearings

- Checking the bevel gear play

- Replacing the disc springs

- Replacing and adjusting

Want to use your machines more productively?

We have training professionals.

Whether you are an operator or a maintenance technician, the more familiar your employees are with MTE, the more productive your machines will be. Our in-house technicians are familiar with every MTE and are happy to share their knowledge with you, either at your premises or on our demonstration machines in Montabaur. Give us a call – we will be happy to advise you!