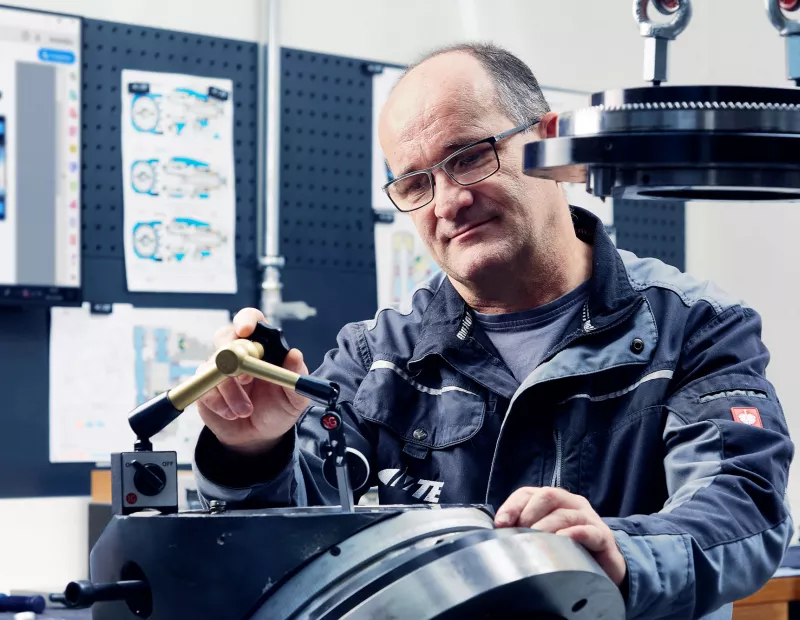

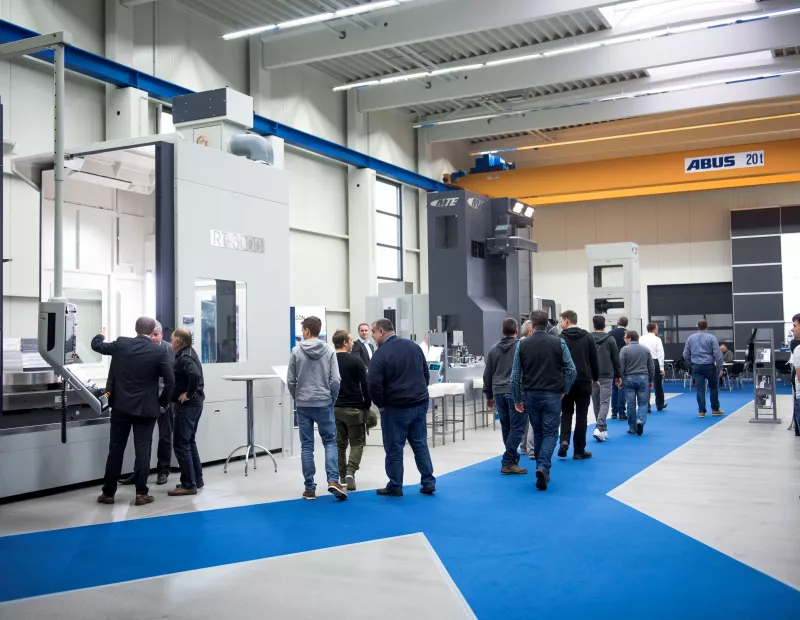

MTE traveling column milling machines –

extensive equipment and extremely wide range of applications

Traveling column milling machines are a winning combination in mechanical engineering, tool and mold making – thanks to their large travel ranges (X up to 36,000, Y up to 5,000 mm) and their extremely high precision thanks to the backlash-free linear roller guide. They enable stepless or indexing milling heads, high rigidity and damping, multitasking with a positioning table or carousel rotary table, pendulum machining, CNC turning and milling on a single machine, automatic milling head changing, and more. In other words: MTE CNC traveling column milling machines are exactly what mechanical engineers want.

Floor type milling machines FBF-S series

Travels

X: 3.000 - 36.000 mm

Y: 1.500 - 2.250 mm

Z: 1.000 - 1.500 mm

Floor type milling machines FBF-M series

Travels

X: 4.000 - 36.000 mm

Y: 2.000 - 3.200 mm

Z: 1.600 mm

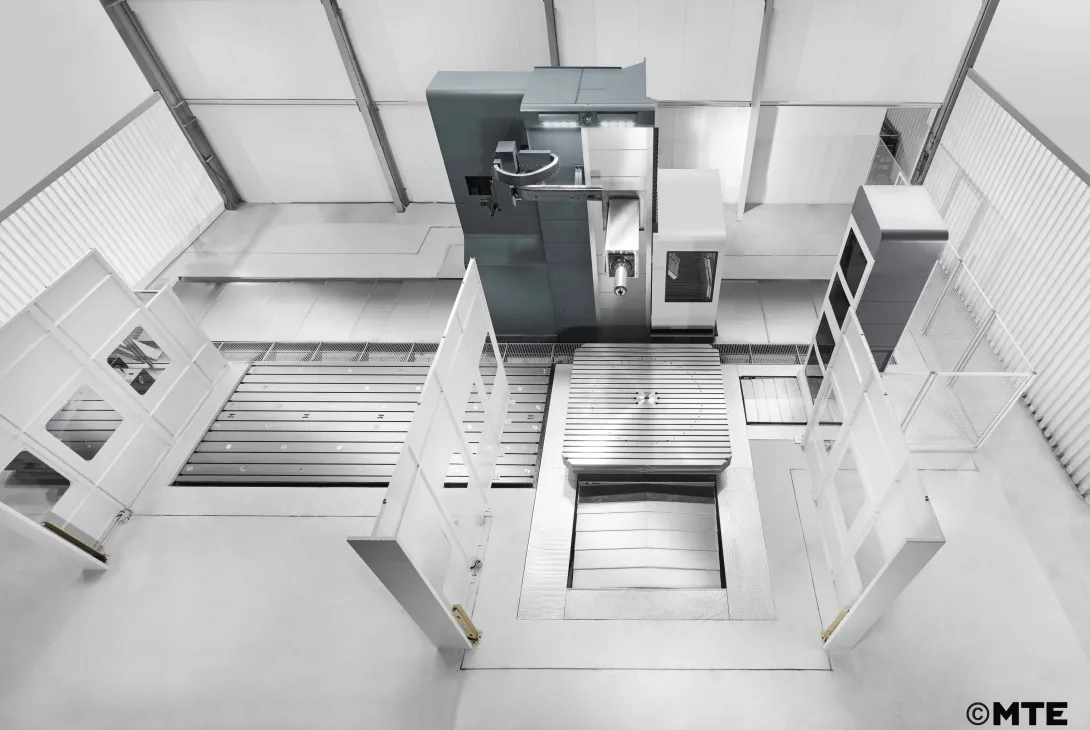

Floor type milling machines FBF-X series

Travels

X: 5.000 - 36.000 mm

Y: 3.000 - 5.300 mm

Z: 1.600 - 1.800 mm