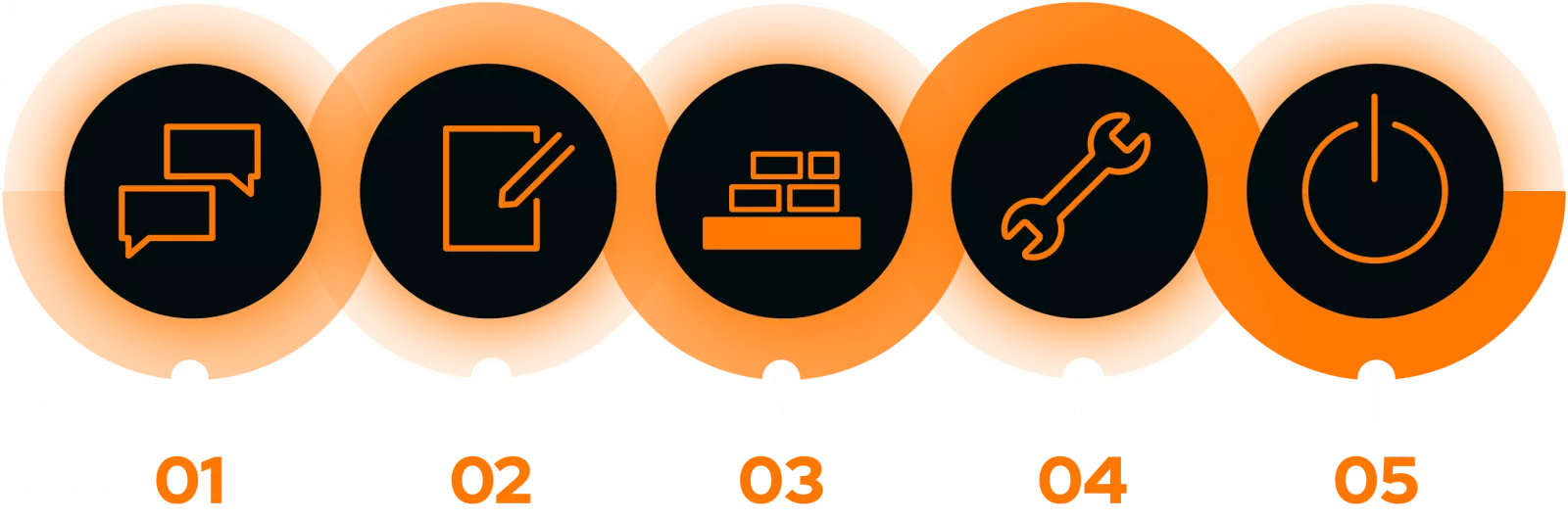

project management

For the right machine for you Our project consulting. We provide comprehensive advice to ensure that your MTE really delivers what you need. Our team asks the right questions – because that's the only way to find the right answers.Need advice? Why not talk to us directly?

Make an appointmentProject consulting

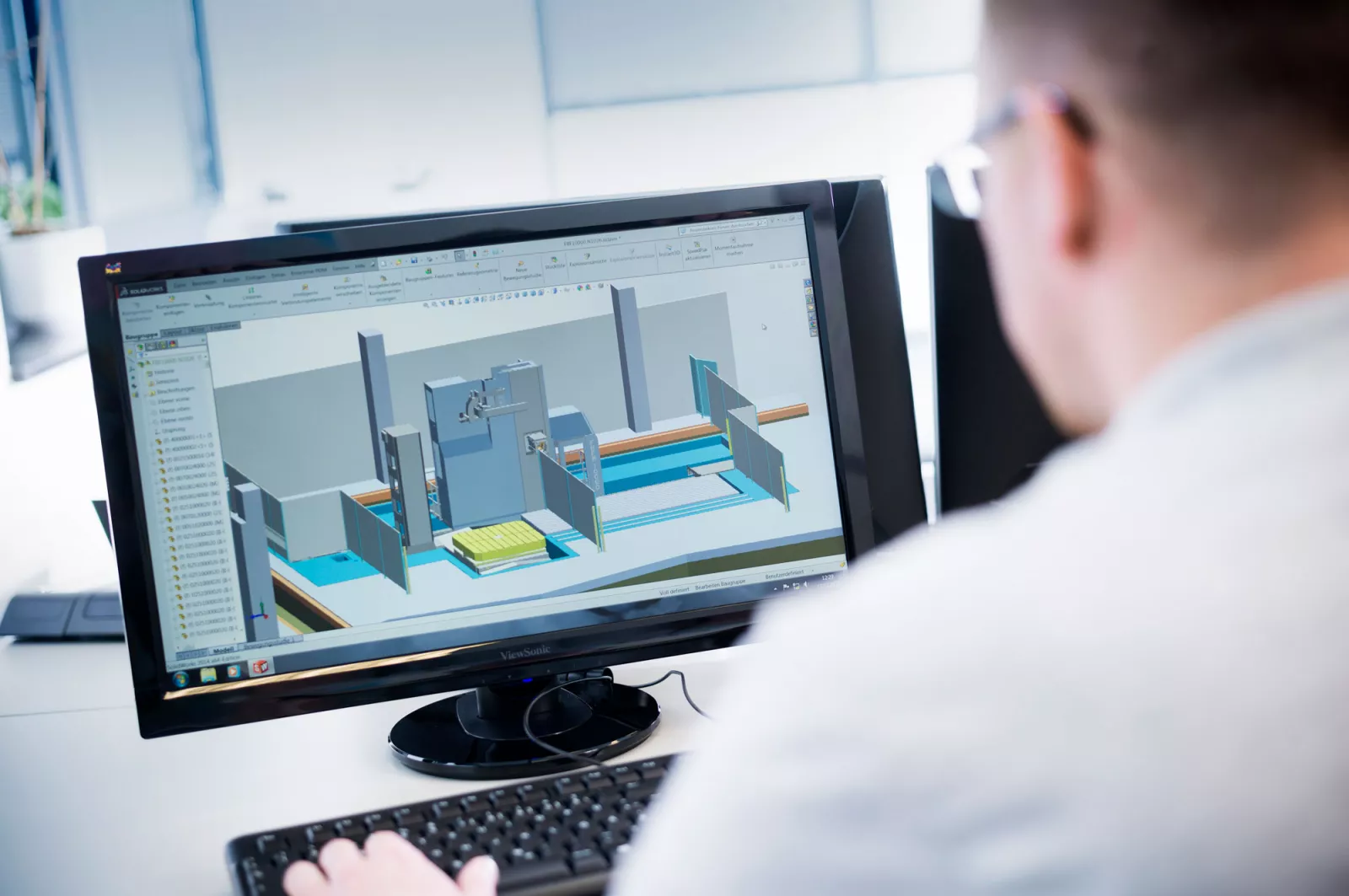

Your bed type milling machines and floor type milling machines must be perfectly tailored to your requirements. That is why it is crucial that we talk to each other. Our employees are the right people to talk to. Working closely with you, they will find out exactly what you need right from the start:

- What exactly does your machine need to do?

- How should it fit into your existing machine park?

- Which features are a must – what would you like to have as an extra?

- What are the conditions on site – which MTE fits perfectly?

Only when these issues – and a few more detailed questions – have been clarified do our experts really get started. They put their heart, expertise and soul into every phase of the project.

Why do our projects run so smoothly?

Because we work as a team to achieve the best results for you.

Our technicians work hand in hand with planners, as well as with specialists from the service and commercial departments. We work with you and your experts to develop the perfect solution for you. Enjoy this individual, comprehensive service with every project!