Linear guided

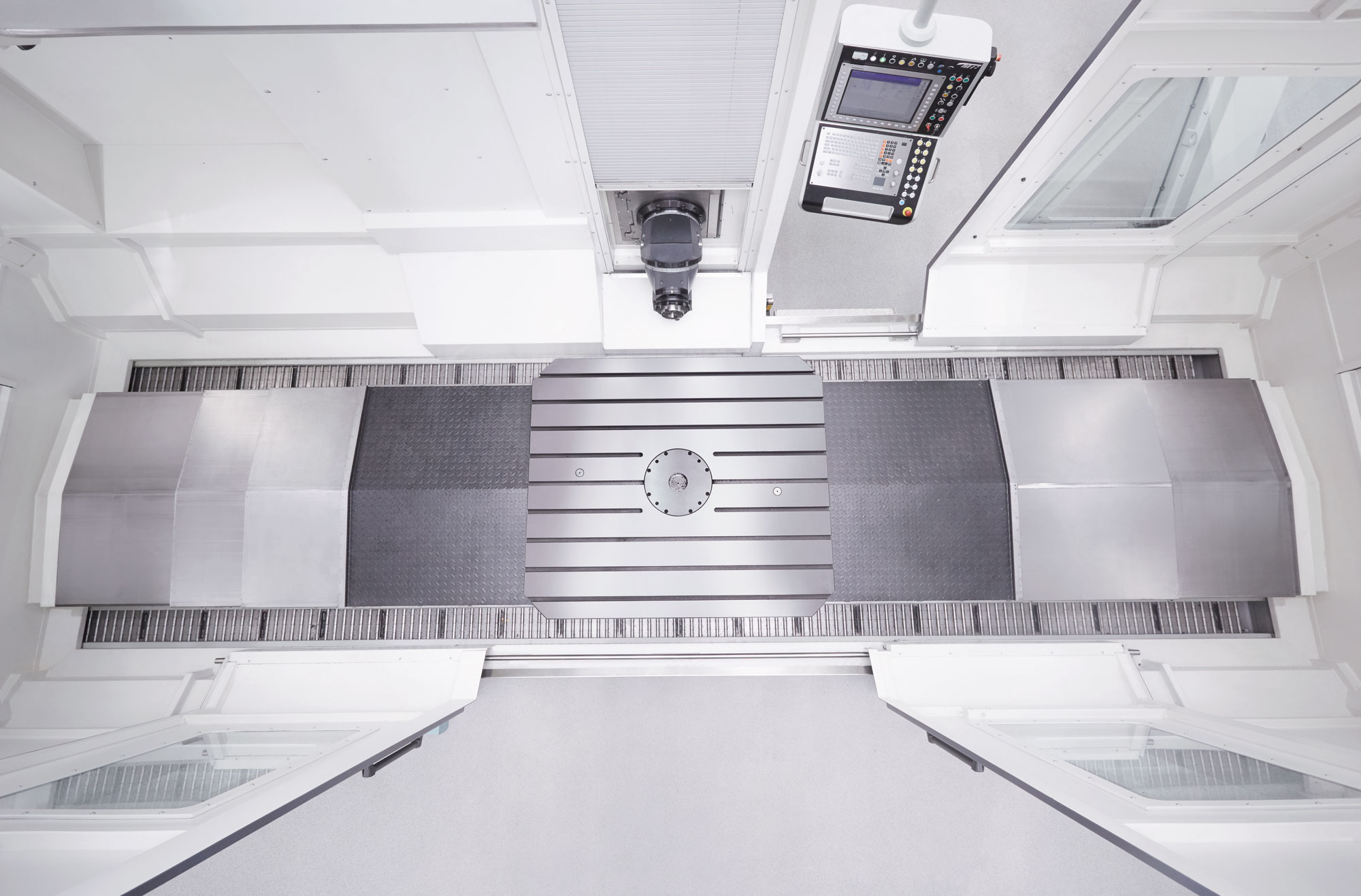

Bed type milling machines

RT series

Travels

X: 2.000 - 4.000 mm

Y: 1.000 - 1.600 mm

Z: 1.000 - 2.000 mm

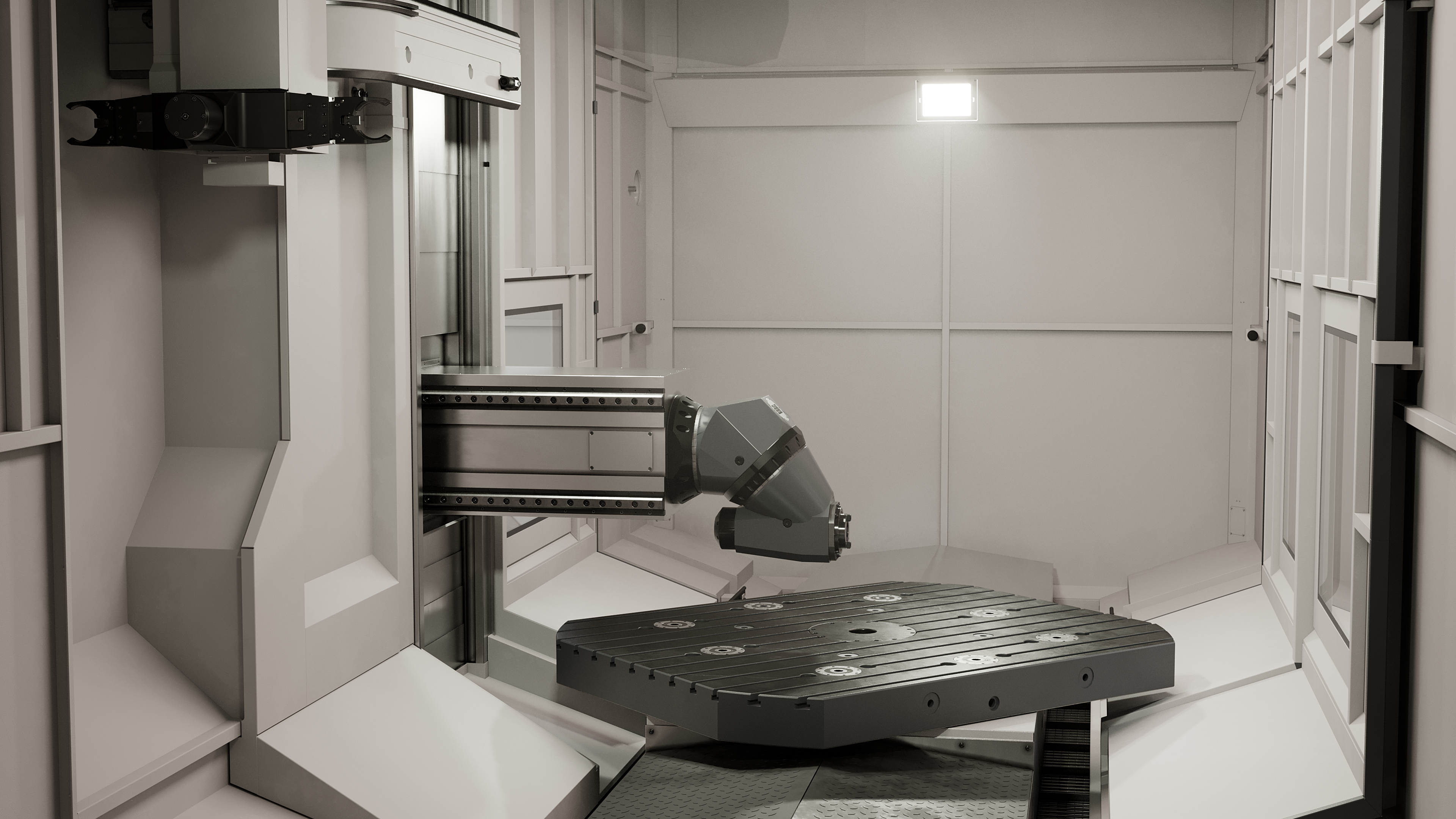

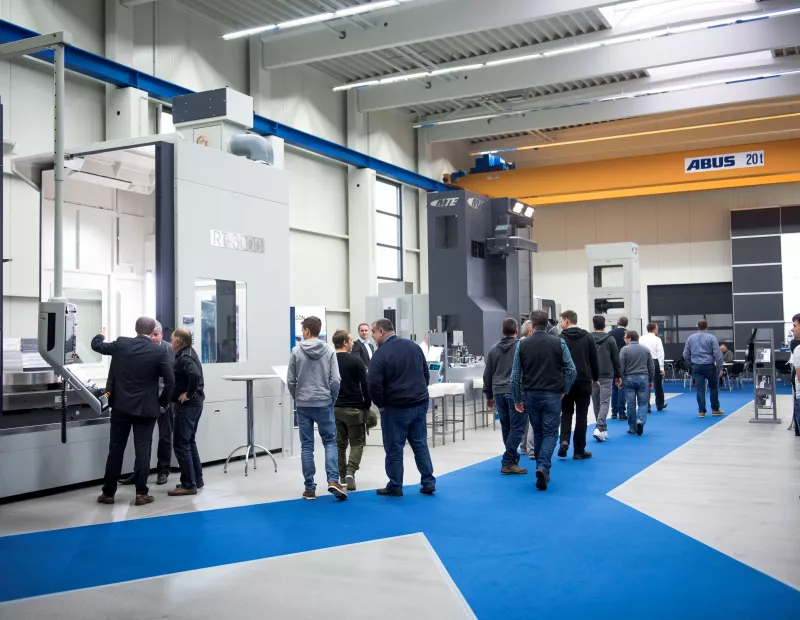

Imagine having all the advantages of a bench-type boring machine – and at the same time those of a bed type milling machine ... Then you can appreciate how clever the concept behind our RT bed type milling machine is. The rotary table integrated as a fourth NC axis is particularly practical. In conjunction with the automatically swivelling milling head, you can machine workpieces on 5 sides and in up to 5 axes. It goes without saying that we also use our vibration-damping and precision-enhancing cast iron construction for the RT bed type milling machine ... Much more interesting is the selection of rotary tables, carousel turning tables and zero-point clamping systems for manual pallet changing. The RT series is optionally available as the RT-V with an additional V-axis (machine stand travel 1,000-2,000 mm).

Fully automatic operation is also possible, of course: in conjunction with a pallet changer for 2-16 storage locations, the RT becomes a universally applicable machining centre for medium and large workpieces weighing up to 20 tonnes.

Fully automatic operation is also possible, of course: in conjunction with a pallet changer for 2-16 storage locations, the RT becomes a universally applicable machining centre for medium and large workpieces weighing up to 20 tonnes.

- Heavily ribbed, vibration-damping cast iron construction of the entire machine

- INA linear guideways on all axes

- Highly dynamic digital drives (25,000 mm/min)

- 43 kW main spindle motor

- Enclosure on 4 sides with 2 front doors and one door at the rear

- Ergonomic handling of workpieces on the machine table thanks to offset front doors

- Interface compatibility

- Effective chip management

- Multitasking: milling and turning on one machine

| Verfahrwege | RT-2000 | RT-2500 | RT-3000 | RT-3500 | RT-4000 | |

|---|---|---|---|---|---|---|

| X-Achse längs | mm | 2.000 | 2.500 | 3.000 | 3.500 | 4.000 |

| Z-Achse vertikal | mm | 1.000 / 1.500 / 2.000 | 1.000 / 1.500 / 2.000 | 1.000 / 1.500 / 2.000 | 1.000 / 1.500 / 2.000 | 1.000 / 1.500 / 2.000 |

| Y-Achse horizontal | mm | 1.000 / 1.200 / 1.300 / 1.500 / 1.600 | 1.000 / 1.200 / 1.300 / 1.500 / 1.600 | 1.000 / 1.200 / 1.300 / 1.500 / 1.600 | 1.000 / 1.200 / 1.300 / 1.500 / 1.600 | 1.000 / 1.200 / 1.300 / 1.500 / 1.600 |

| Tisch | RT-2000 | RT-2500 | RT-3000 | RT-3500 | RT-4000 | |

|---|---|---|---|---|---|---|

| Aufspannfläche-Schaltteller (Optional) | mm | 1.000-2.500x1.000-2.000 | 1.000-2.500x1.000-2.000 | 1.000-2.500x1.000-2.000 | 1.000-2.500x1.000-2.000 | 1.000-2.500x1.000-2.000 |

| max. zul. Tischbelastung (Optional) | Kg | 8.000-20.000 | 8.000-20.000 | 8.000-20.000 | 8.000-20.000 | 8.000-20.000 |

| Spindel | RT-2000 | RT-2500 | RT-3000 | RT-3500 | RT-4000 | |

|---|---|---|---|---|---|---|

| Spindeldrehzahlbereiche | U/min. | 4.000-6.000 | 4.000-6.000 | 4.000-6.000 | 4.000-6.000 | 4.000-6.000 |

| Leistung | Kw | 32/43/65 | 32/43/65 | 32/43/65 | 32/43/65 | 32/43/65 |

| Drehmoment bei 43kW 4000/6000 U/min. | Nm | 920-2020 (S1) | 920-2020 (S1) | 920-2020 (S1) | 920-2020 (S1) | 920-2020 (S1) |

| Autom. Schwenkkopf: diagonal | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | |

| Autom. Schwenkkopf: orthogonal | 1°x1° | 1°x1° | 1°x1° | 1°x1° | 1°x1° |

| Vorschübe | RT-2000 | RT-2500 | RT-3000 | RT-3500 | RT-4000 | |

|---|---|---|---|---|---|---|

| Eilgang (X/Y/Z) max. | mm/min. | 25.000 | 25.000 | 25.000 | 25.000 | 25.000 |

| Arbeitsvorschub (X/Y/Z) max. | mm/min. | 15.000 | 15.000 | 15.000 | 15.000 | 15.000 |

| Vorschubkraft (X/Y/Z) max. | N | 21.500 | 21.500 | 21.500 | 21.500 | 21.500 |

| Platzbedarf | RT-2000 | RT-2500 | RT-3000 | RT-3500 | RT-4000 | |

|---|---|---|---|---|---|---|

| Länge (ohne Querförderer+1280) | mm | 5.900 | 6.700 | 7.350 | 8.100 | 8.900 |

| Höhe bei Z=1500 (2000) ohne WZW | mm | 3.600 (4.100) | 3.600 (4.100) | 3.600 (4.100) | 3.600 (4.100) | 3.600 (4.100) |

| Breite bei Y=1.200 (1.300 / 1.500) | mm | 5.580 (5.870 / 6.400) | 5.580 (5.870 / 6.400) | 5.580 (5.870 / 6.400) | 5.580 (5.870 / 6.400) | 5.580 (5.870 / 6.400) |

| Breite bei W-Achse (Optional) | mm | +1.000-2.000 | +1.000-2.000 | +1.000-2.000 | +1.000-2.000 | +1.000-2.000 |

| Weitere Daten | RT-2000 | RT-2500 | RT-3000 | RT-3500 | RT-4000 | |

|---|---|---|---|---|---|---|

| Werkzeugwechsler Random | Plätze | 24 | 24 | 24 | 24 | 24 |

| Werkzeugwechsler H/V-Kette | Plätze | 40 / 60 / 80 / 100 / 120 | 40 / 60 / 80 / 100 / 120 | 40 / 60 / 80 / 100 / 120 | 40 / 60 / 80 / 100 / 120 | 40 / 60 / 80 / 100 / 120 |

| IKZ und Außenkühlung Luft und/oder Wasser | bar | 20-70 | 20-70 | 20-70 | 20-70 | 20-70 |

| CNC Steuerung | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens |

Highlights der Maschine

You can find all the highlights on the machine card.

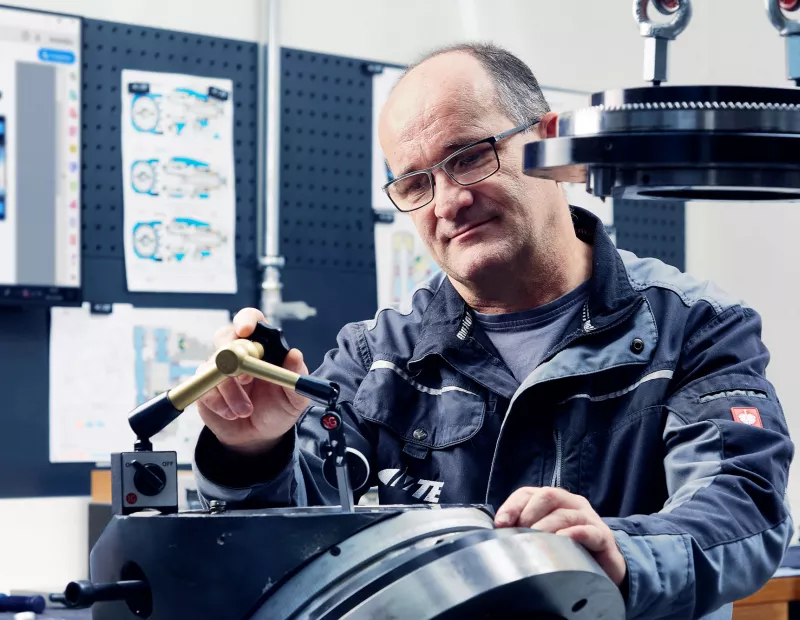

linear guideway

- Backlash-free linear roller guide for maximum accuracy

- Low friction for high dynamics in 2.5/3-D machining

- High rigidity thanks to a large number of roller recirculation units and larger rollers

- Low maintenance and wear costs

positioning

- Automatic stepless positioning 0.001°x0.001°

- High stability thanks to extremely large clamping (Ina YRT bearing)

- Rigidity thanks to cast steel housing

- High torques

multitask

- Multifunctional machine through the use of carousel turning tables

- Turning on the machine with Capto C5/C6 tool holders

- Automatic turning tool change possible

- Grinding on the machine with grinding spindle

ergonomics

- Easy access to the clamping table

- Low noise emissions

- Intelligent chip management for less cleaning work