Linear guided

Bed type milling machines

RT-V series

Travels

X: 2.000 - 4.000 mm

Y: 1.500 - 1.600 mm

Z: 1.500 - 2.000 mm

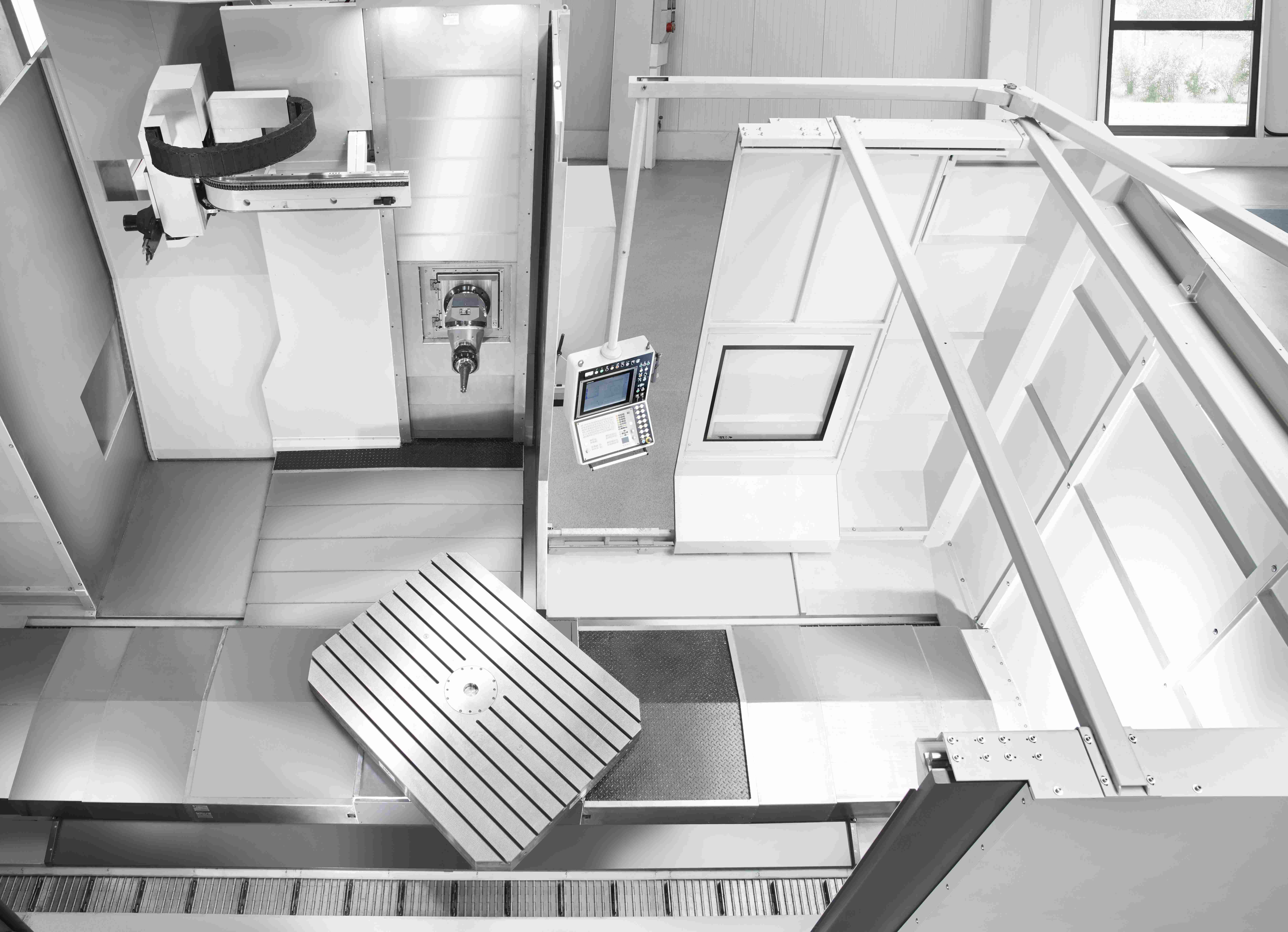

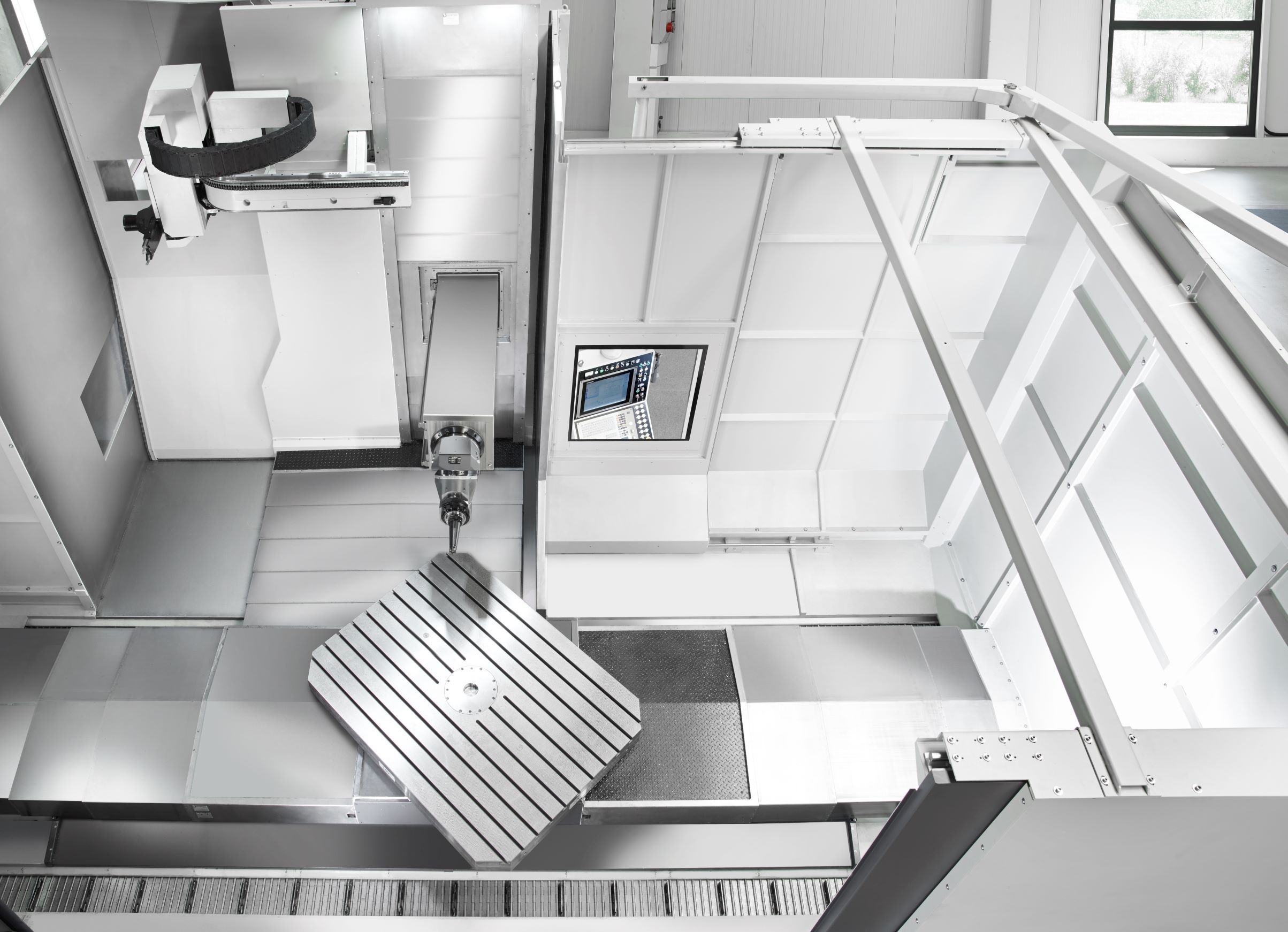

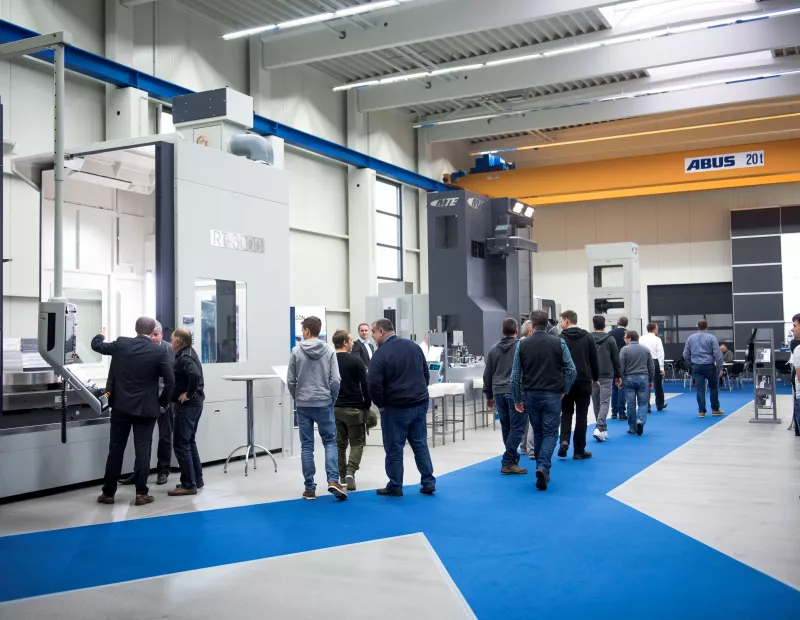

The RT-V is specially designed for efficient and precise multi-sided machining of large workpieces weighing up to 60 tonnes.

With travel distances of 3,000 to 4,000 mm in the X-axis and rotary table sizes from 2,000 x 2,000 mm to 3,000 x 3,000 mm, workpieces can be flexibly positioned and, if required, also carousel turning. Added to this are the well-designed enclosure and the movable stand: together, these ensure a good view even with large swing diameters of 2,500 to 4,000 mm and excellent chip removal.

The new series thus enables high-precision multi-sided machining in the smallest of spaces, especially for large workpieces and with extremely long tools, for example in deep drilling. As usual with MTE, the new RT-V series is also made entirely of cast iron with generously dimensioned guides. The control system, available from Heidenhain or Siemens, is also standard.

With travel distances of 3,000 to 4,000 mm in the X-axis and rotary table sizes from 2,000 x 2,000 mm to 3,000 x 3,000 mm, workpieces can be flexibly positioned and, if required, also carousel turning. Added to this are the well-designed enclosure and the movable stand: together, these ensure a good view even with large swing diameters of 2,500 to 4,000 mm and excellent chip removal.

The new series thus enables high-precision multi-sided machining in the smallest of spaces, especially for large workpieces and with extremely long tools, for example in deep drilling. As usual with MTE, the new RT-V series is also made entirely of cast iron with generously dimensioned guides. The control system, available from Heidenhain or Siemens, is also standard.

- Heavily ribbed, vibration-damping cast construction of the entire machine

- INA linear guideways on all axes

- Highly dynamic digital drives (25,000 mm/min)

- 43 kW water-cooled main spindle motor (inline)

- Enclosure individually adapted to the interference circle diameter

- Interface reliability

- Effective chip management

- Multitasking: milling and turning on one machine

| Verfahrwege | RT-V-2000 | RT-V-2500 | RT-V-3000 | RT-V-3500 | RT-V-4000 | |

|---|---|---|---|---|---|---|

| X-Achse längs | mm | 2.000 | 2.500 | 3.000 | 3.500 | 4.000 |

| Z-Achse vertikal | mm | 1.500 / 2.000 | 1.500 / 2.000 | 1.500 / 2.000 | 1.500 / 2.000 | 1.500 / 2.000 |

| Y-Achse horizontal | mm | 1.500 - 1.600 | 1.500 - 1.600 | 1.500 - 1.600 | 1.500 - 1.600 | 1.500 - 1.600 |

| V-Achse | mm | 1.000-3.000 | 1.000-3.000 | 1.000-3.000 | 1.000-3.000 | 1.000-3.000 |

| TIsch | RT-V-2000 | RT-V-2500 | RT-V-3000 | RT-V-3500 | RT-V-4000 | |

|---|---|---|---|---|---|---|

| Aufspannfläche (Option) | mm | 1.400 - 3.000 x 1.400 - 3.000 | 1.400 - 3.000 x 1.400 - 3.000 | 1.400 - 3.000 x 1.400 - 3.000 | 1.400 - 3.000 x 1.400 - 3.000 | 1.400 - 3.000 x 1.400 - 3.000 |

| max. zul. Tischbelastung | kg | 15.000 - 60.000 | 15.000 - 60.000 | 15.000 - 60.000 | 15.000 - 60.000 | 15.000 - 60.000 |

| Spindel | RT-V-2000 | RT-V-2500 | RT-V-3000 | RT-V-3500 | RT-V-4000 | |

|---|---|---|---|---|---|---|

| Spindeldrehzahlbereiche | U/min. | 4.000-6.000 | 4.000-6.000 | 4.000-6.000 | 4.000-6.000 | 4.000-6.000 |

| Leistung | Kw | 32/43/65 | 32/43/65 | 32/43/65 | 32/43/65 | 32/43/65 |

| Drehmoment bei 43kW 4000/6000 U/min. | Nm | 920 - 2.020 | 920 - 2.020 | 920 - 2.020 | 920 - 2.020 | 920 - 2.020 |

| Autom. Schwenkkopf: diagonal | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | |

| Autom. Schwenkkopf: orthogonal | 1°x1° | 1°x1° | 1°x1° | 1°x1° | 1°x1° |

| Vorschübe | RT-V-2000 | RT-V-2500 | RT-V-3000 | RT-V-3500 | RT-V-4000 | |

|---|---|---|---|---|---|---|

| Eilgang (X/Y/Z) max. | mm/min. | 25.000 | 25.000 | 25.000 | 25.000 | 25.000 |

| Arbeitsvorschub (X/Y/Z) max. | mm/min. | 15.000 | 15.000 | 15.000 | 15.000 | 15.000 |

| Vorschubkraft (X/Y/Z) max. | N | 26.000 | 26.000 | 26.000 | 26.000 | 26.000 |

| Weitere Daten | RT-V-2000 | RT-V-2500 | RT-V-3000 | RT-V-3500 | RT-V-4000 | |

|---|---|---|---|---|---|---|

| Werkzeugwechsler Random | Plätze | 24 | 24 | 24 | 24 | 24 |

| Werkzeugwechsler H/V-Kette | Plätze | 40 / 60 / 80 / 100 / 120 | 40 / 60 / 80 / 100 / 120 | 40 / 60 / 80 / 100 / 120 | 40 / 60 / 80 / 100 / 120 | 40 / 60 / 80 / 100 / 120 |

| IKZ und Außenkühlung Luft und/oder Wasser | bar | 20-70 | 20-70 | 20-70 | 20-70 | 20-70 |

| CNC Steuerung | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens |

Highlights der Maschine

You can find all the highlights on the machine card.

linear guideway

- Backlash-free linear roller guide for maximum accuracy

- Low friction for high dynamics in 2.5/3-D machining

- High rigidity thanks to a large number of roller recirculation units and larger rollers

- Low maintenance and wear costs

positioning

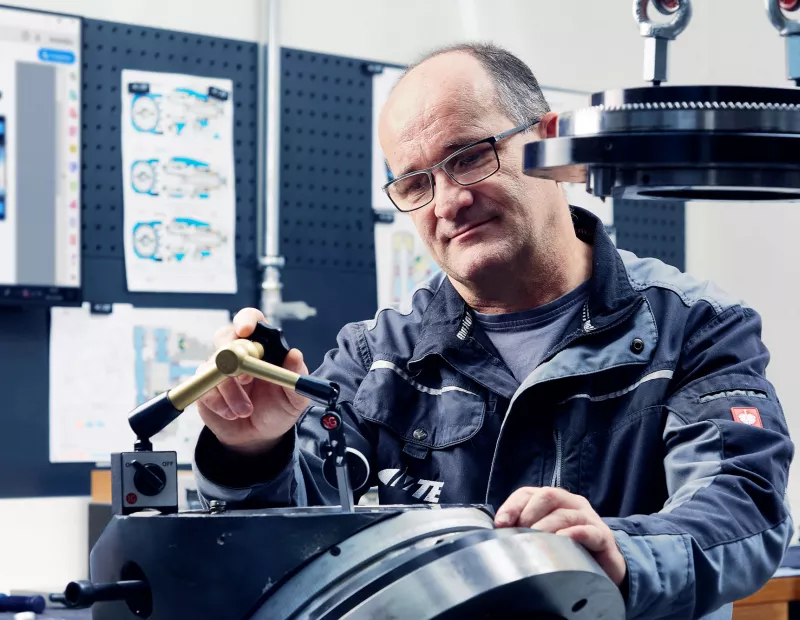

- Automatic stepless positioning 0.001°x0.001°

- High stability thanks to extremely large clamping (Ina YRT bearing)

- Rigidity thanks to cast steel housing

- High torques

multitask

- Multifunctional machine through the use of carousel turning tables

- Turning on the machine with Capto C5/C6 tool holders

- Automatic turning tool change possible

- Grinding on the machine with grinding spindle

ergonomics

- Easy access to the clamping table

- Low noise emissions

- Intelligent chip management for less cleaning work