Floor type milling machines

FBF-M series

Travels

X: 4.000 - 36.000 mm

Y: 2.000 - 3.200 mm

Z: 1.600 mm

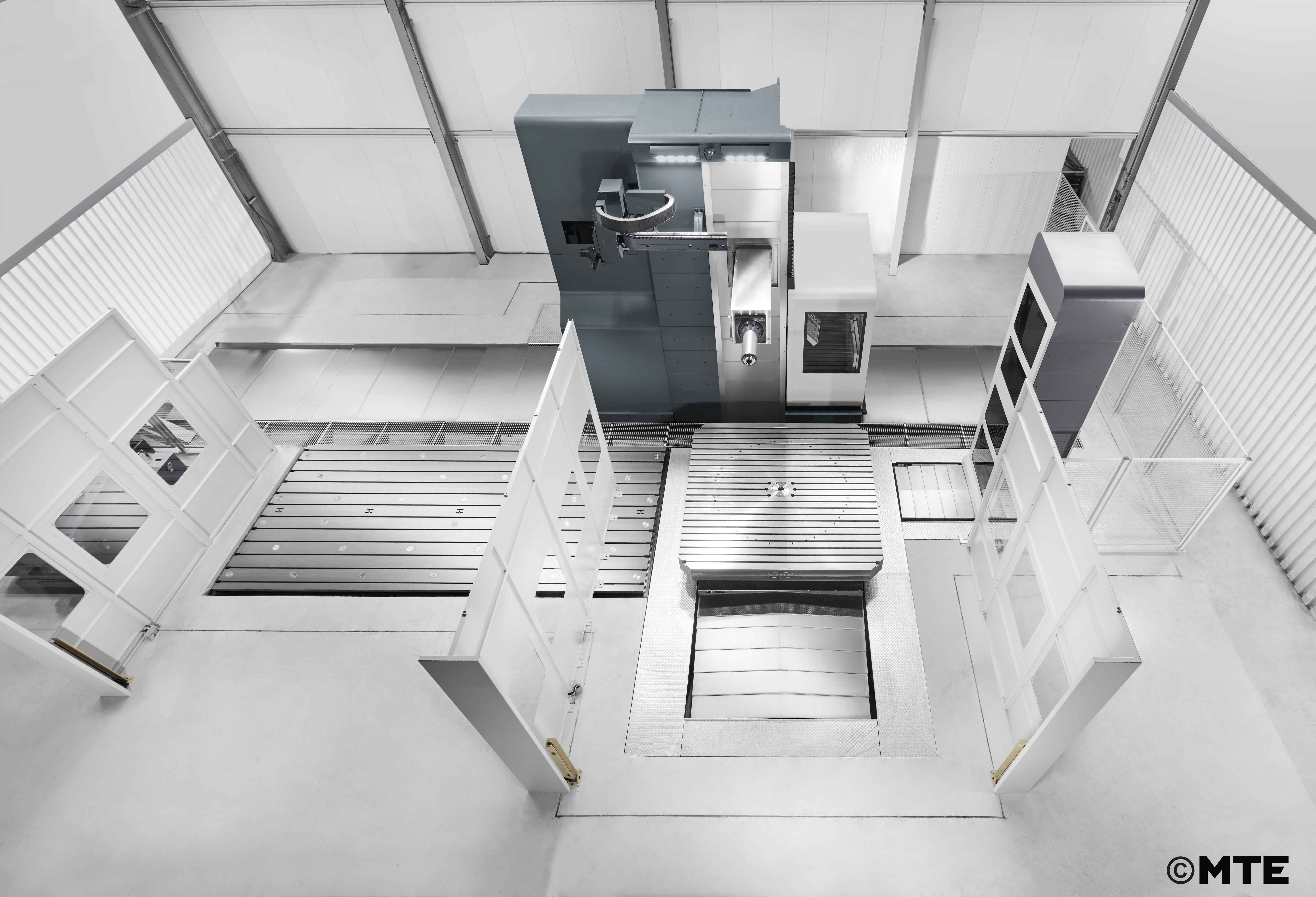

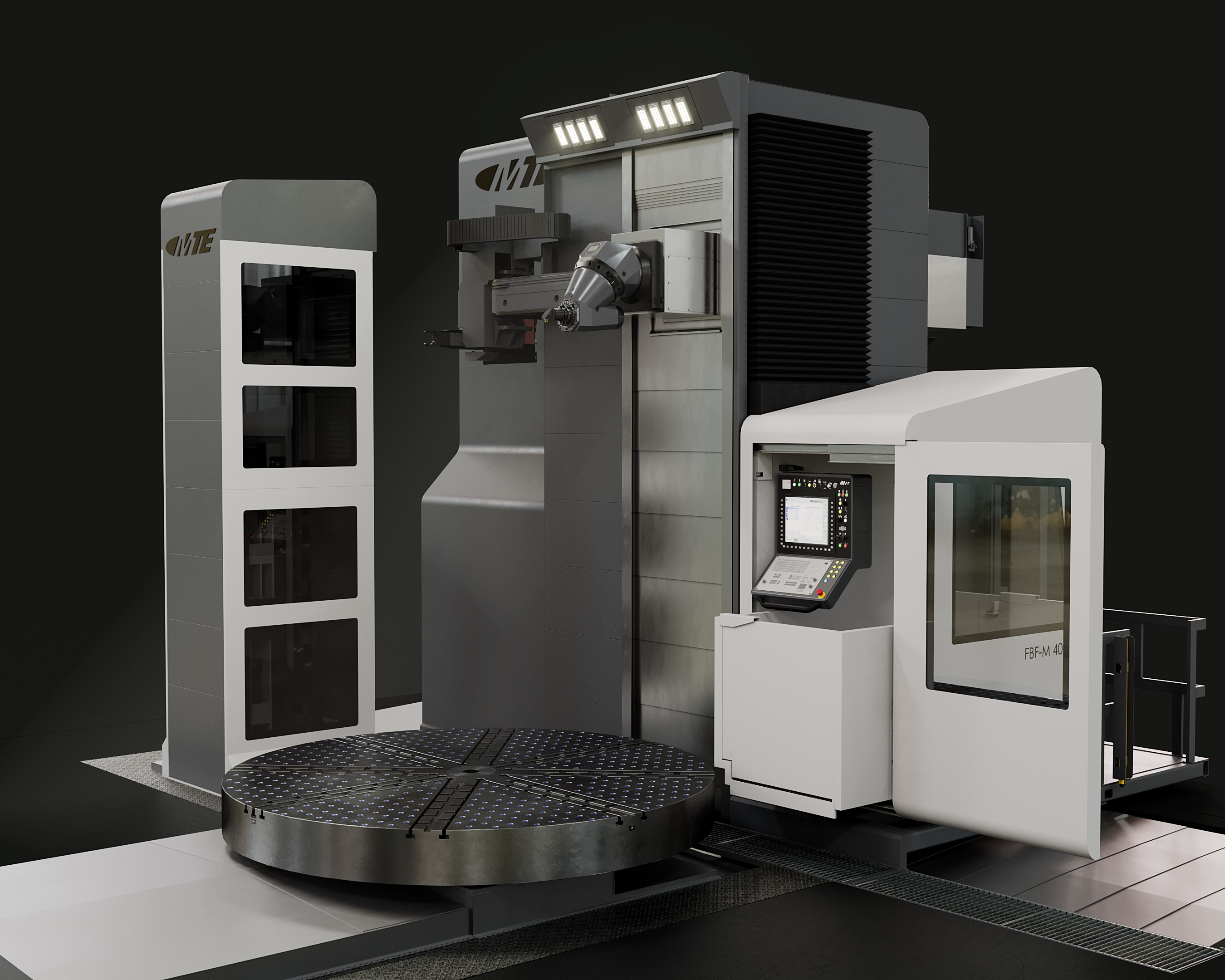

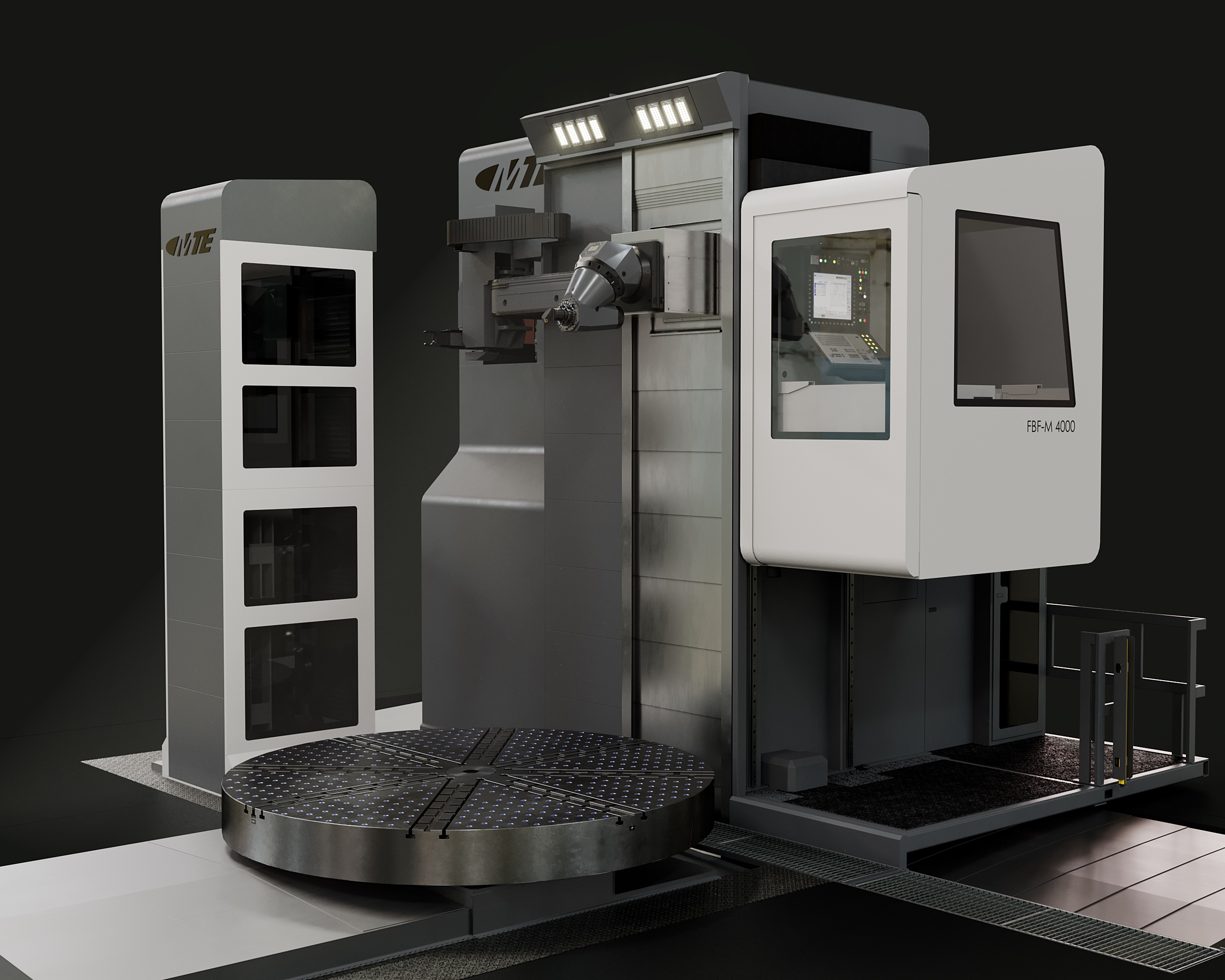

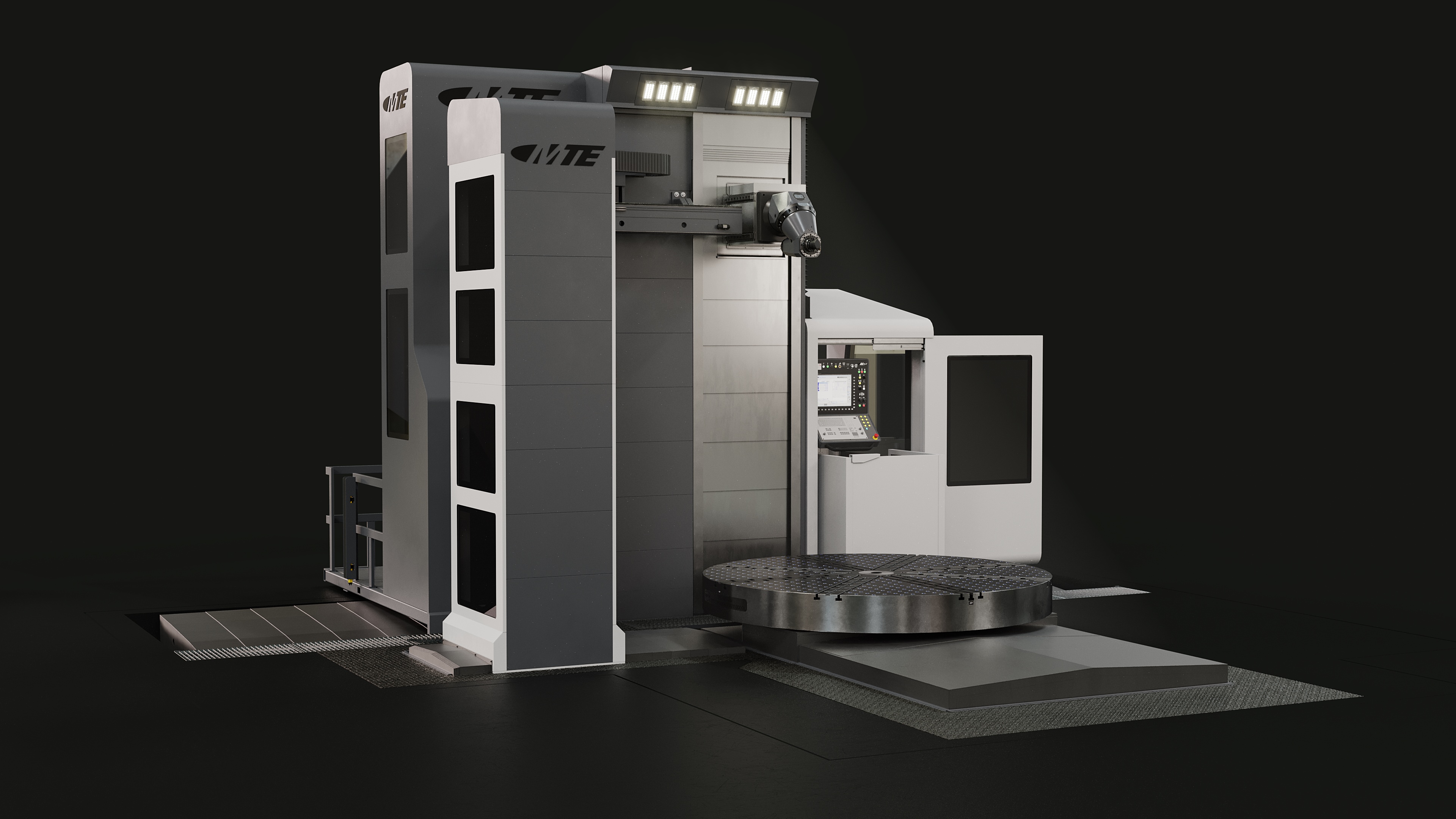

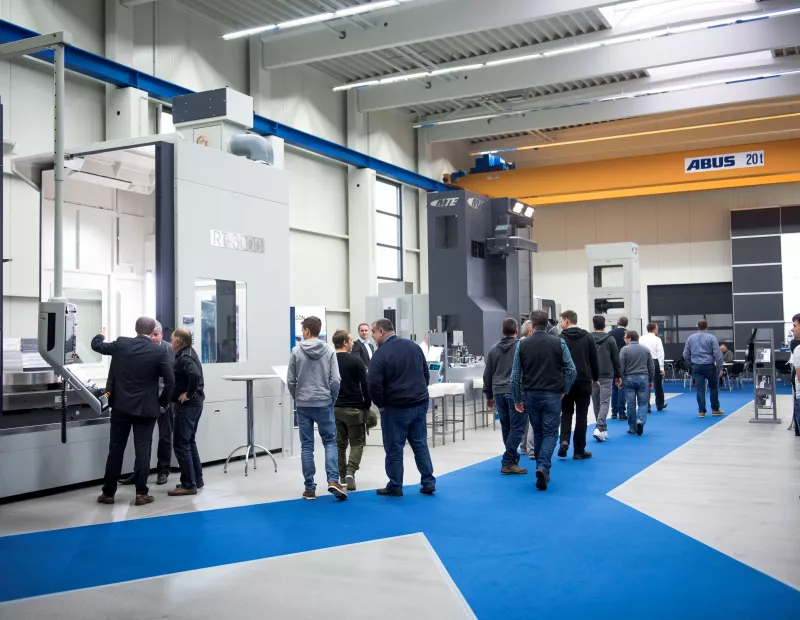

As the name suggests, the FBF-M is one size larger than our FBF-S. More precisely, it can process workpieces up to 3,200 mm high in the vertical travel direction. It primarily demonstrates its strengths for our customers in mechanical engineering. This is undoubtedly due to its very high flexibility.

The fully automatic milling head changing system, which you can use on the FBF-M travelling column machine, is extremely practical. You can equip the FBF-M with up to 4 different (interchangeable) milling heads. Pendulum machining is also available as an option. This gives you maximum flexibility. By using rotary tables, with or without an additional traverse axis, particularly large and heavy workpieces can be machined on up to 5 sides in a single clamping. For all these reasons, the FBF-M is also frequently used for machining complex large tool moulds made of high-strength materials.

The fully automatic milling head changing system, which you can use on the FBF-M travelling column machine, is extremely practical. You can equip the FBF-M with up to 4 different (interchangeable) milling heads. Pendulum machining is also available as an option. This gives you maximum flexibility. By using rotary tables, with or without an additional traverse axis, particularly large and heavy workpieces can be machined on up to 5 sides in a single clamping. For all these reasons, the FBF-M is also frequently used for machining complex large tool moulds made of high-strength materials.

- Heavily ribbed, vibration-damping cast iron construction of the entire machine

- INA linear guideways on all axes

- Highly dynamic digital drives (25,000 mm/min)

- 43 kW main spindle motor

- Spacious and ergonomic operator platform, optionally height- and crosswise adjustable

- Individually adapted and practical enclosure

- Interface compatibility

- Multitasking: milling and turning on one machine

| Verfahrwege | FBF-M 4000 | FBF-M 5000 | FBF-M 6000 | FBF-M 7000 | FBF-M 8000 | FBF-M 9000 | FBF-M 10000 | FBF-M 12000 | FBF-M 14000 | |

|---|---|---|---|---|---|---|---|---|---|---|

| X-Achse längs | mm | 4.000 | 5.000 | 6.000 | 7.000 | 8.000 | 9.000 | 10.000 | 12.000 | 14.000 |

| Y-Achse vertikal | mm | 2.000 / 2.500 / 3.000 / 3.200 | 2.000 / 2.500 / 3.000 / 3.200 | 2.000 / 2.500 / 3.000 / 3.200 | 2.000 / 2.500 / 3.000 / 3.200 | 2.000 / 2.500 / 3.000 / 3.200 | 2.000 / 2.500 / 3.000 / 3.200 | 2.000 / 2.500 / 3.000 / 3.200 | 2.000 / 2.500 / 3.000 / 3.200 | 2.000 / 2.500 / 3.000 / 3.200 |

| Z-Achse horizontal | mm | 1.600 | 1.600 | 1.600 | 1.600 | 1.600 | 1.600 | 1.600 | 1.600 | 1.600 |

| Spindel | FBF-M 4000 | FBF-M 5000 | FBF-M 6000 | FBF-M 7000 | FBF-M 8000 | FBF-M 9000 | FBF-M 10000 | FBF-M 12000 | FBF-M 14000 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Spindeldrehzahlbereiche | 4.000 - 6.000 | 4.000 - 6.000 | 4.000 - 6.000 | 4.000 - 6.000 | 4.000 - 6.000 | 4.000 - 6.000 | 4.000 - 6.000 | 4.000 - 6.000 | 4.000 - 6.000 | |

| Leistung | Kw | 43/65 | 43/65 | 43/65 | 43/65 | 43/65 | 43/65 | 43/65 | 43/65 | 43/65 |

| Drehmoment bei 43kW 4000/6000 U/min. | Nm | 920-2.020 (S1) | 920-2.020 (S1) | 920-2.020 (S1) | 920-2.020 (S1) | 920-2.020 (S1) | 920-2.020 (S1) | 920-2.020 (S1) | 920-2.020 (S1) | 920-2.020 (S1) |

| Autom. Schwenkkopf: diagonal | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | 0,001°x0,001° / 0,01°x0,01° / 2,5°x1° / 2,5°x2,5° | |

| Autom. Schwenkkopf: orthogonal | 1° × 1° | 1° × 1° | 1° × 1° | 1° × 1° | 1° × 1° | 1° × 1° | 1° × 1° | 1° × 1° | 1° × 1° |

| Vorschübe | FBF-M 4000 | FBF-M 5000 | FBF-M 6000 | FBF-M 7000 | FBF-M 8000 | FBF-M 9000 | FBF-M 10000 | FBF-M 12000 | FBF-M 14000 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Eilgang (X/Y/Z) max. | mm/min. | 25.000 | 25.000 | 25.000 | 25.000 | 25.000 | 25.000 | 25.000 | 25.000 | 25.000 |

| Platzbedarf | FBF-M 4000 | FBF-M 5000 | FBF-M 6000 | FBF-M 7000 | FBF-M 8000 | FBF-M 9000 | FBF-M 10000 | FBF-M 12000 | FBF-M 14000 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Länge (ohne Querförderer+1280) | mm | 11.600 | 11.600 | 11.600 | 13.600 | 13.600 | 15.600 | 15.600 | 17.600 | 17.600 |

| Höhe bei Y=2000 (2500/3000) | mm | 4.700 (5.200 / 5.800) | 4.700 (5.200 / 5.800) | 4.700 (5.200 / 5.800) | 4.700 (5.200 / 5.800) | 4.700 (5.200 / 5.800) | 4.700 (5.200 / 5.800) | 4.700 (5.200 / 5.800) | 4.700 (5.200 / 5.800) | 4.700 (5.200 / 5.800) |

| Breite bei Z=1600 | mm | 5.180 | 5.180 | 5.180 | 5.180 | 5.180 | 5.180 | 5.180 | 5.180 | 5.180 |

| Weitere Daten | FBF-M 4000 | FBF-M 5000 | FBF-M 6000 | FBF-M 7000 | FBF-M 8000 | FBF-M 9000 | FBF-M 10000 | FBF-M 12000 | FBF-M 14000 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Werkzeugwechsler Random | Plätze | - | - | - | - | - | - | - | - | - |

| Werkzeugwechsler H/V-Kette | Plätze | 40 / 60 / 80/ 100 / 120 | 40 / 60 / 80/ 100 / 120 | 40 / 60 / 80/ 100 / 120 | 40 / 60 / 80/ 100 / 120 | 40 / 60 / 80/ 100 / 120 | 40 / 60 / 80/ 100 / 120 | 40 / 60 / 80/ 100 / 120 | 40 / 60 / 80/ 100 / 120 | 40 / 60 / 80/ 100 / 120 |

| IKZ und Außenkühlung Luft und/oder Wasser | bar | 20-70 | 20-70 | 20-70 | 20-70 | 20-70 | 20-70 | 20-70 | 20-70 | 20-70 |

| CNC Steuerung | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens |

Highlights der Maschine

You can find all the highlights on the machine card.

linear guideway

- Backlash-free linear roller guide for maximum accuracy

- Low friction for high dynamics in 2.5/3-D machining

- High rigidity thanks to a large number of roller recirculation units and larger rollers

- Low maintenance and wear costs

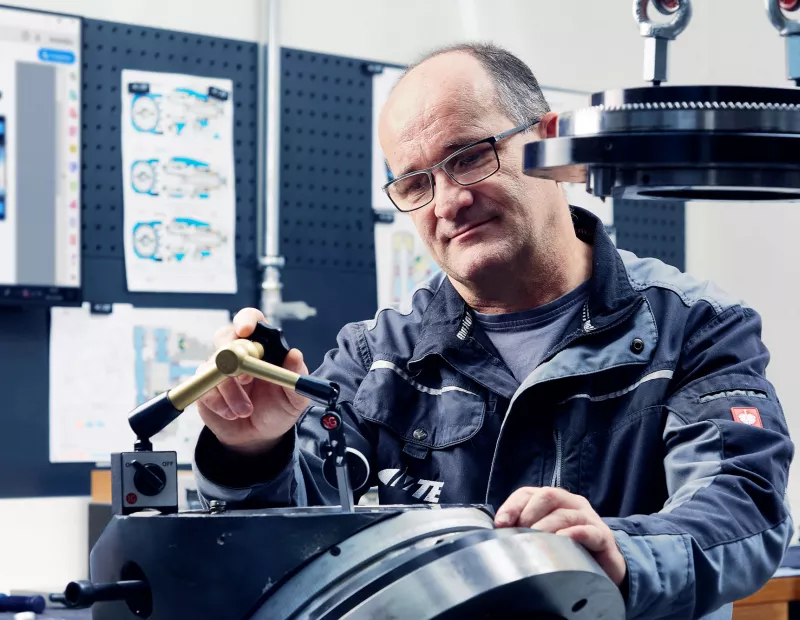

positioning

- Automatic stepless positioning 0.001°x0.001°

- High stability thanks to extremely large clamping (Ina YRT bearing)

- Rigidity thanks to cast steel housing

- High torques

multitask

- Multifunctional machine through the use of carousel turning tables

- Turning on the machine with Capto C5/C6 tool holders

- Automatic turning tool change possible

- Grinding on the machine with grinding spindle

FEM

- Designed according to FEM

- Greater rigidity and damping

- Insensitive to minor collisions and tool breakage

- Vibration-free without electromechanical compensation systems