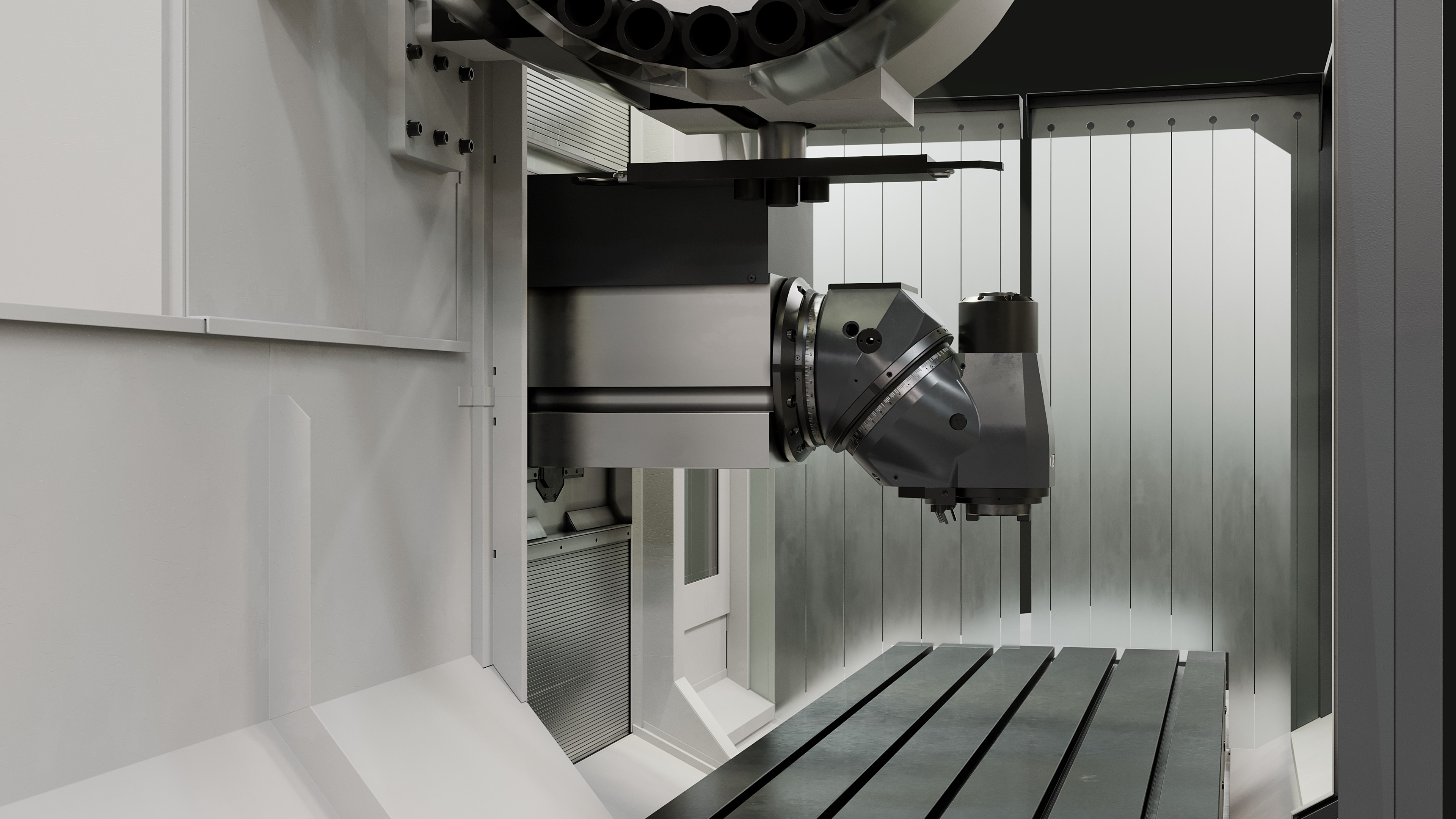

Our K board milling machine combines power with precision. This is ensured by the standard 24 kW main spindle motor and the 2-stage gearbox. Overall, the machine has a compact design. At the same time, it impresses with its large travel distances. This makes it the ideal machine for machining small and medium-sized workpieces.

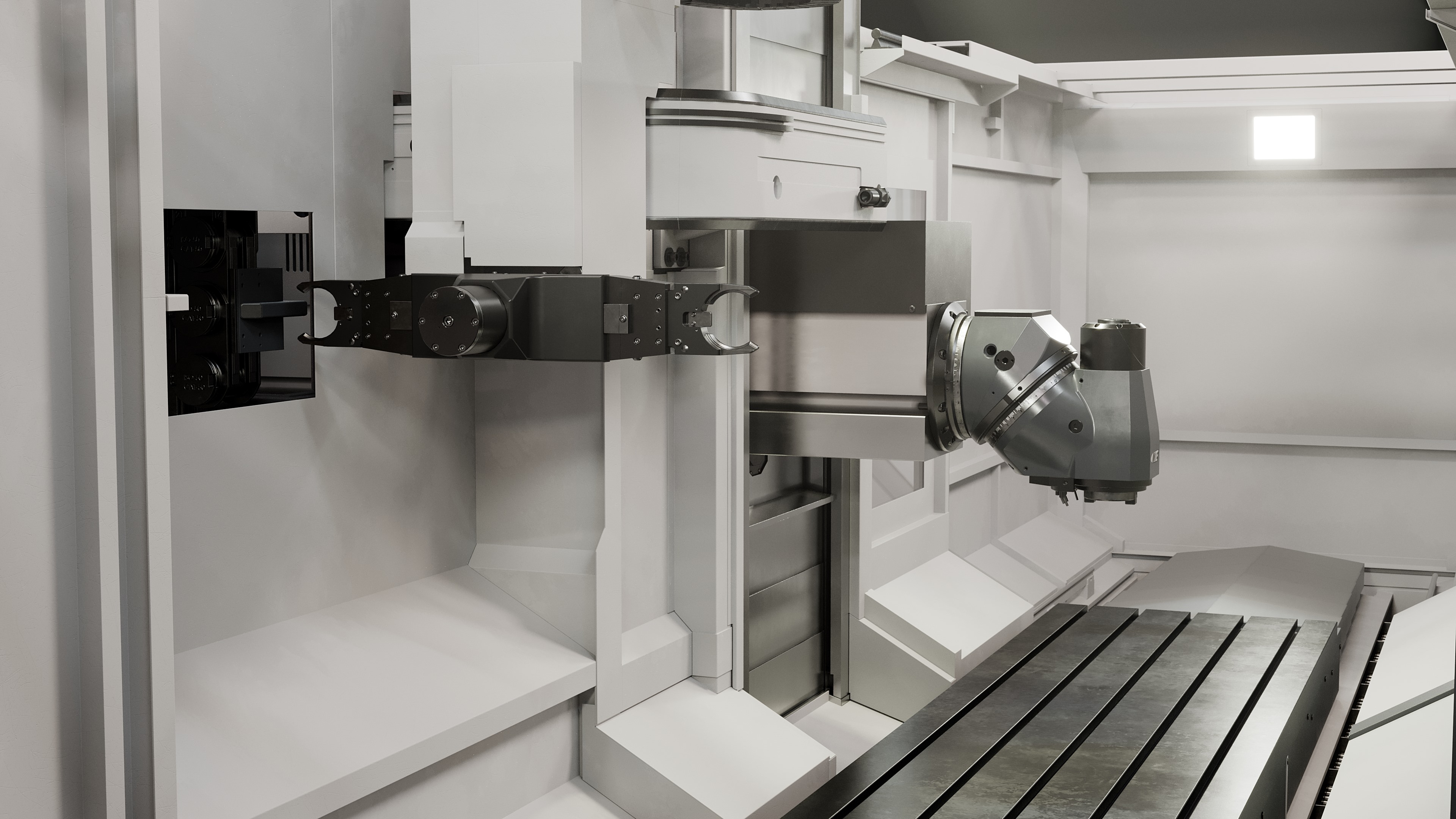

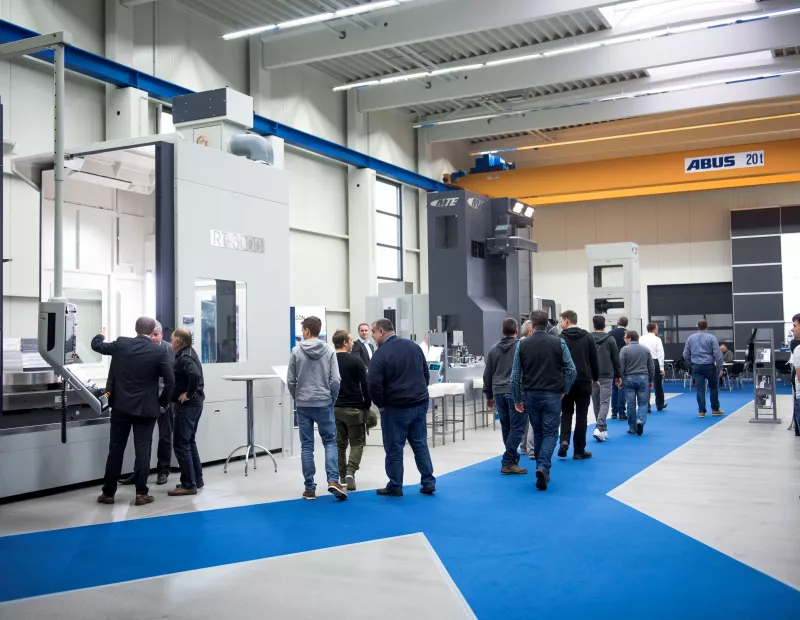

We design your K machine exactly as you want it – with manual or automatic swivelling milling head, with or without tool changer, with full enclosure or simple splash guard slats for protruding workpieces. Do you have any further requirements? We will be happy to meet them!

We design your K machine exactly as you want it – with manual or automatic swivelling milling head, with or without tool changer, with full enclosure or simple splash guard slats for protruding workpieces. Do you have any further requirements? We will be happy to meet them!

- Heavily ribbed, vibration-damping cast construction of the entire machine

- Flat guides: hardened and ground guideways with Turcite B-coated opposite side

- Highly dynamic digital drives (15,000 mm/min)

- 24 kW main spindle motor

- 2-stage gearbox in the ram

- Enclosure on 4 sides with 2 front doors and one door at the rear

- Ergonomic handling of workpieces on the machine table thanks to offset front doors

- Interface compatibility

- Effective chip management

More information in the machine data sheet download

| Verfahrwege | K2200 | K2700 | K3200 | K3700 | K4200 | K4700 | K5200 | |

|---|---|---|---|---|---|---|---|---|

| X-Achse längs | mm | 2.000 | 2.500 | 3.000 | 3.500 | 4.000 | 4.500 | 5.000 |

| Y-Achse horizontal | mm | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Z-Achse vertikal | mm | 1.100 | 1.100 | 1.100 | 1.100 | 1.100 | 1.100 | 1.100 |

| Tisch | K2200 | K2700 | K3200 | K3700 | K4200 | K4700 | K5200 | |

|---|---|---|---|---|---|---|---|---|

| Aufspannfläche | mm | 2.200x850 | 2.700x850 | 3.200x850 | 3.700 | 4.200 | 4.700 | 5.200 |

| max. zul. Tischbelastung | Kg | 4.500 | 6.000 | 7.500 |

| Spindel (2-stufiges-Getriebe) | K2200 | K2700 | K3200 | K3700 | K4200 | K4700 | K5200 | |

|---|---|---|---|---|---|---|---|---|

| Spindeldrehzahlbereiche | U/min | 3.000-6.000 | 3.000-6.000 | 3.000-6.000 | 3.000-6.000 | 3.000-6.000 | 3.000-6.000 | 3.000-6.000 |

| Leistung | Kw | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

| Drehmoment 4000 U/min. / 6000 U/min. | Nm | 1.020 / 740 | 1.020 / 740 | 1.020 / 740 | 1.020 / 740 | 1.020 / 740 | 1.020 / 740 | 1.020 / 740 |

| Autom. Schwenkkopf: diagonal | 2,5° × 2,5° | 2,5° × 2,5° | 2,5° × 2,5° | 2,5° × 2,5° | 2,5° × 2,5° | 2,5° × 2,5° | 2,5° × 2,5° |

| Vorschübe | K2200 | K2700 | K3200 | K3700 | K4200 | K4700 | K5200 | |

|---|---|---|---|---|---|---|---|---|

| Eilgang (X/Y/Z) max. | mm/min. | 15.000 | 15.000 | 15.000 | 15.000 | 15.000 | 15.000 | 15.000 |

| Arbeitsvorschub (X/Y/Z) max. | mm/min. | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 |

| Platzbedarf | K2200 | K2700 | K3200 | K3700 | K4200 | K4700 | K5200 | |

|---|---|---|---|---|---|---|---|---|

| Länge (ohne Querförderer+1280) | mm | 6.400 | 7.400 | 7.400 | ||||

| Breite | mm | 3.100 | 3.100 | 3.100 | 3.100 | 3.100 | 3.100 | 3.100 |

| Höhe | mm | 4.000 | 4.000 | 4.000 | 4.000 | 4.000 | 4.000 | 4.000 |

| Weitere Daten | K2200 | K2700 | K3200 | K3700 | K4200 | K4700 | K5200 | |

|---|---|---|---|---|---|---|---|---|

| Werkzeugwechsler Random | Plätze | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

| Werkzeugwechsler H/V-Kette | Plätze | 40/60 | 40/60 | 40/60 | 40/60 | 40/60 | 40/60 | 40/60 |

| IKZ und Außenkühlung Luft und/oder Wasser | bar | 20-70 | 20-70 | 20-70 | 20-70 | 20-70 | 20-70 | 20-70 |

| CNC Steuerung | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens | Heidenhain / Siemens |

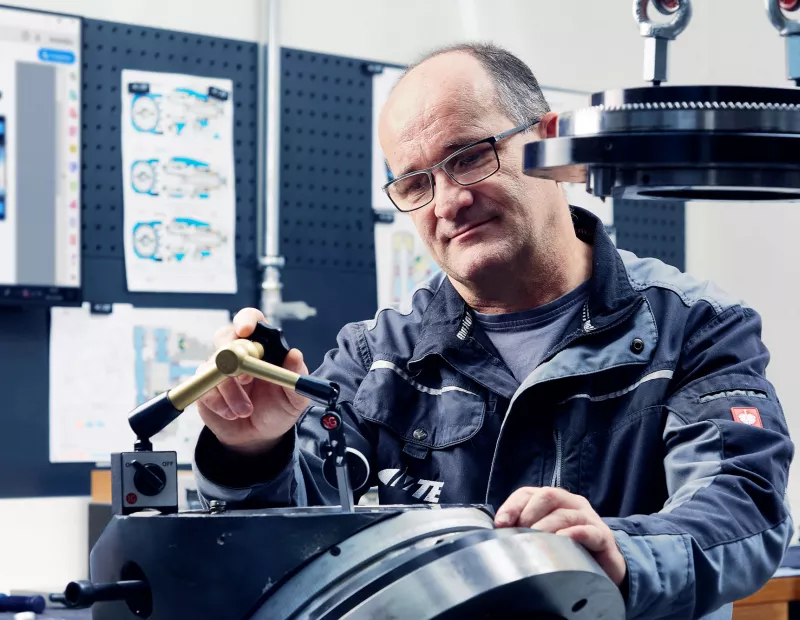

Highlights der Maschine

You can find all the highlights on the machine card.

Flat guide

- Longer service life thanks to extremely high damping, especially in heavy-duty machining

- Easy adjustment options

- Insensitive to minor collisions

FEM

- Designed according to FEM

- Greater rigidity and damping

- Insensitive to minor collisions and tool breakage

- Vibration-free without electromechanical compensation systems

ergonomics

- Easy access to the clamping table

- Low noise emissions

- Intelligent chip management for less cleaning work

Environment

- Avoiding unnecessary consumption of resources

- Reducing environmentally harmful measures

- Intelligent, needs-based switch cabinet and hydraulic solutions