A double pack of bed type milling machines

BBG Mindelheim solves complex requirements with two MTE bed type milling machinesWhen the requirements profile is complex, the obvious solution is not necessarily the best one. At BBG Mindelheim, an international supplier of manufacturing technologies for joining glass and plastic, simply replacing a 30-year-old boring machine was not enough. MTE developed a flexible, long-term solution for the customer and ultimately prevailed with this approach.

Would you like to know more about the impressive features of MTE bed type milling machines? Then take a look at the profiles of the BF and RT series.

Demanding requirements

Component sizes up to 3 by 2 metres, weights of up to 15 tonnes and chip removal rates of up to 70 percent: the list of requirements for the new machine was extremely demanding. And ideally, the operator should be able to leave the hall after start-up, leaving the machine running stably and reliably and enabling unmanned machining times that are as long as possible. Who wouldn't want that?

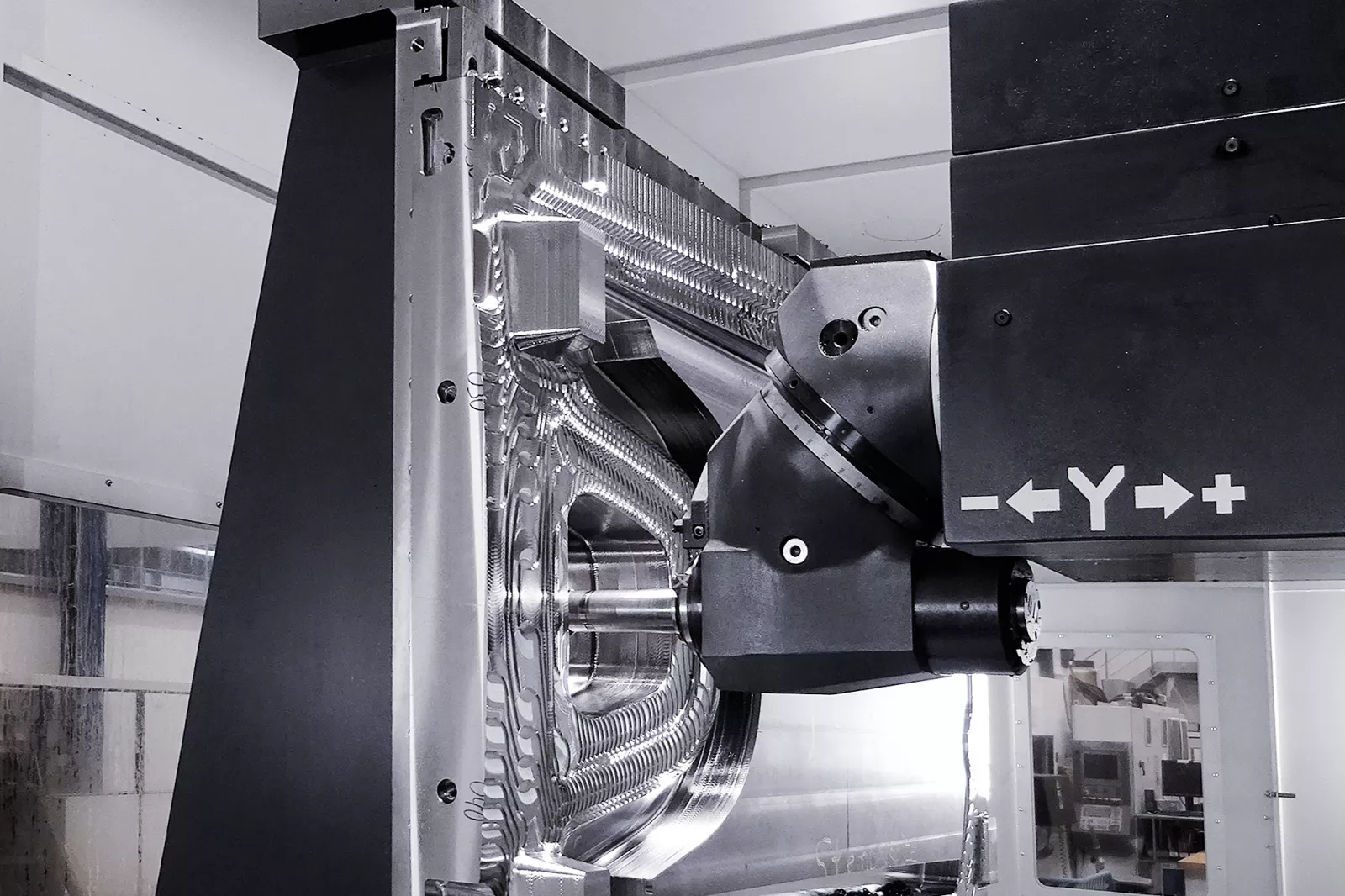

Intelligent double pack

It is almost impossible to achieve this scenario with just one machine. Our proposal therefore focused on an intelligent double pack: two MTE bed type milling machines that complement each other perfectly. With its flat guides, the BF 3700 is ideal for roughing due to its stability and good-natured operation. The RT 3000 rotary table machine, with its large tool magazine with 100 positions and infinitely variable milling head, is flexible enough for complete five-sided external machining of moulds and tools. Both machines are also equipped with Brankamp tool monitoring.

Safe and sophisticated

This means that even long machining operations with many tool changes run with 100 percent process reliability and enable the required long unmanned machining times. A sophisticated underfloor chip management system also ensures that large quantities of chips are transported fully automatically from the hall to a large container.

Convincing across the board

The creative and technically sophisticated MTE double pack concept ultimately prevailed in the selection process – not least because it was backed up by our convincing service promise. When it came to the availability of spare parts and loan milling heads, we were the only supplier who could credibly promise to remedy any machine downtime in the shortest possible time.

Versatile winner

With our MTE BF 3700 and RT 3000 bed type milling machines, BBG Mindelheim will increase unmanned running times and process reliability, significantly reduce set-up times and save up to 50 percent of the time required for complex machining operations. A result we are rather proud of.

Would you like to write a success story together with MTE? Please feel free to contact us!