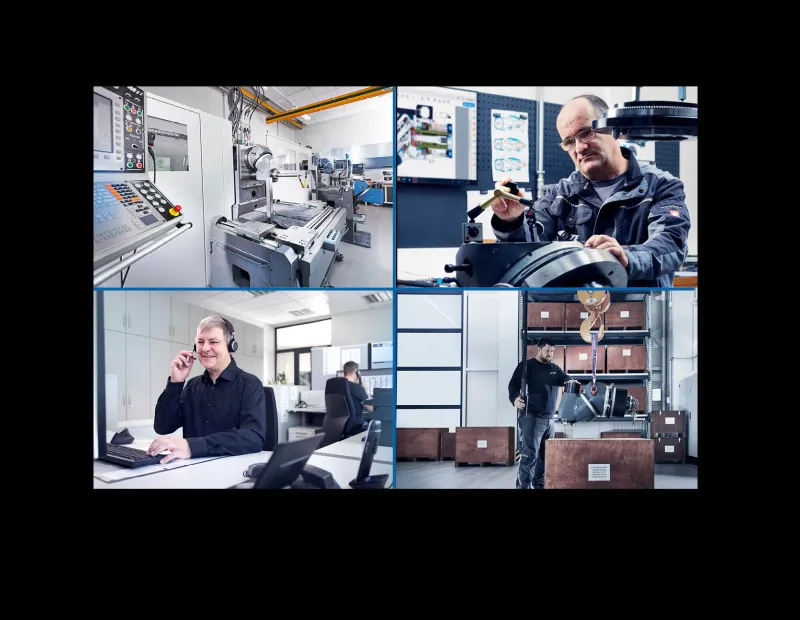

Heavy-duty machining with maximum precision: Why Sommer Döhlau relies on the MTE BF 3200.

Sommer in Döhlau manufactures high-tech façades in aesthetically sophisticated architecture, certified building physics elements for building safety and highly developed building components for hazard prevention. For parts weighing up to 10 tonnes and tolerances of just one hundredth of a millimetre, an MTE BF 3200 bed type milling machine has been ensuring efficiency and accuracy in large-part machining since 2019.As a rule, small series, often with batch sizes of 1, are milled on the BF 3200. Because Sommer relies on a high level of vertical integration in-house, the variety of components produced is large. It ranges from sheet metal parts to classic machine engineering workpieces. This can even include a 10-tonne door for the combustion chamber of a fusion reactor. Here, the required accuracy is only one hundredth of a millimetre, a tolerance that can be reliably maintained with the BF 3200. The tools used at Sommer can weigh up to 20 kg and be 450 mm long – no problem for our bed type milling machine, which has a particularly large tool magazine with 40 slots at Sommer.

Fast tool changes, short set-up times

While the head had to be laboriously adjusted manually on the previous machine, this is done automatically in a few seconds on the BF 3200. Large tool magazine, automatic head adjustment, plus the hydraulic Hilma-Römheld clamping devices. With our machine, Sommer not only works more accurately, but also significantly more productively. The automatic milling head only caused concern at the beginning. A look at our MTE head workshop showed those responsible that they are in good hands in the event of an emergency. Our own test benches, experienced technicians and more than 40 replacement milling heads that are always ready for use ensure minimum downtimes.

Internal cooling for good chip removal

The MTE BF 3200 is equipped with 20 bar internal cooling. The internal coolant supply offers particular advantages when drilling. The strips produced in summer often have holes up to 250 mm deep. The internal cooling system ensures that chips are removed particularly efficiently in this case too. The Heidenhain TNC 640 control system on the MTE BF 3200 meant that the operators at Sommer were working in familiar territory. They had already worked with older Heidenhain control systems and quickly found their way around.