Heavy-duty machining tools make mammoth tasks easier

Solutions suitable for heavy-duty clamping process work extremely hard workpiecesWhether wear-resistant materials for construction machinery or alloyed and tempered tool steels for tool and mould making: wherever extremely hard materials are processed, this means heavy-duty work for the machines and is a mammoth task even for professionals. Machines suitable for heavy-duty machining make this work easier.

MTE machines have this heavy-duty machining capability. Click here to go directly to our products: Product overview

In the defence industry, in tool, mould and rail construction, in casting machining and in wind power: basically wherever workpieces are more highly alloyed and have a lot of material allowance – i.e. where a lot of material has to be removed – the industry refers to heavy-duty machining. Heavy-duty machines are required for these heavy-duty machining tasks.

What exactly is heavy-duty machining in milling?

First of all, there is no universal and clear-cut definition of heavy-duty machining. Heavy-duty machining, also known as HPC (high-performance cutting), refers to a work process that involves high feed rates and high productivity. However, heavy-duty machining also refers to the machining of large components and geometries, such as industrial gearboxes, shafts and drives for commercial vehicles, construction machinery or parts for shipbuilding, railway construction, agriculture and mining. Another focus is the energy sector. Whether in wind power, gas-fired power plants or hydrogen technology, large, heavy, tough and hard components are machined everywhere.

High demands on extremely hard materials

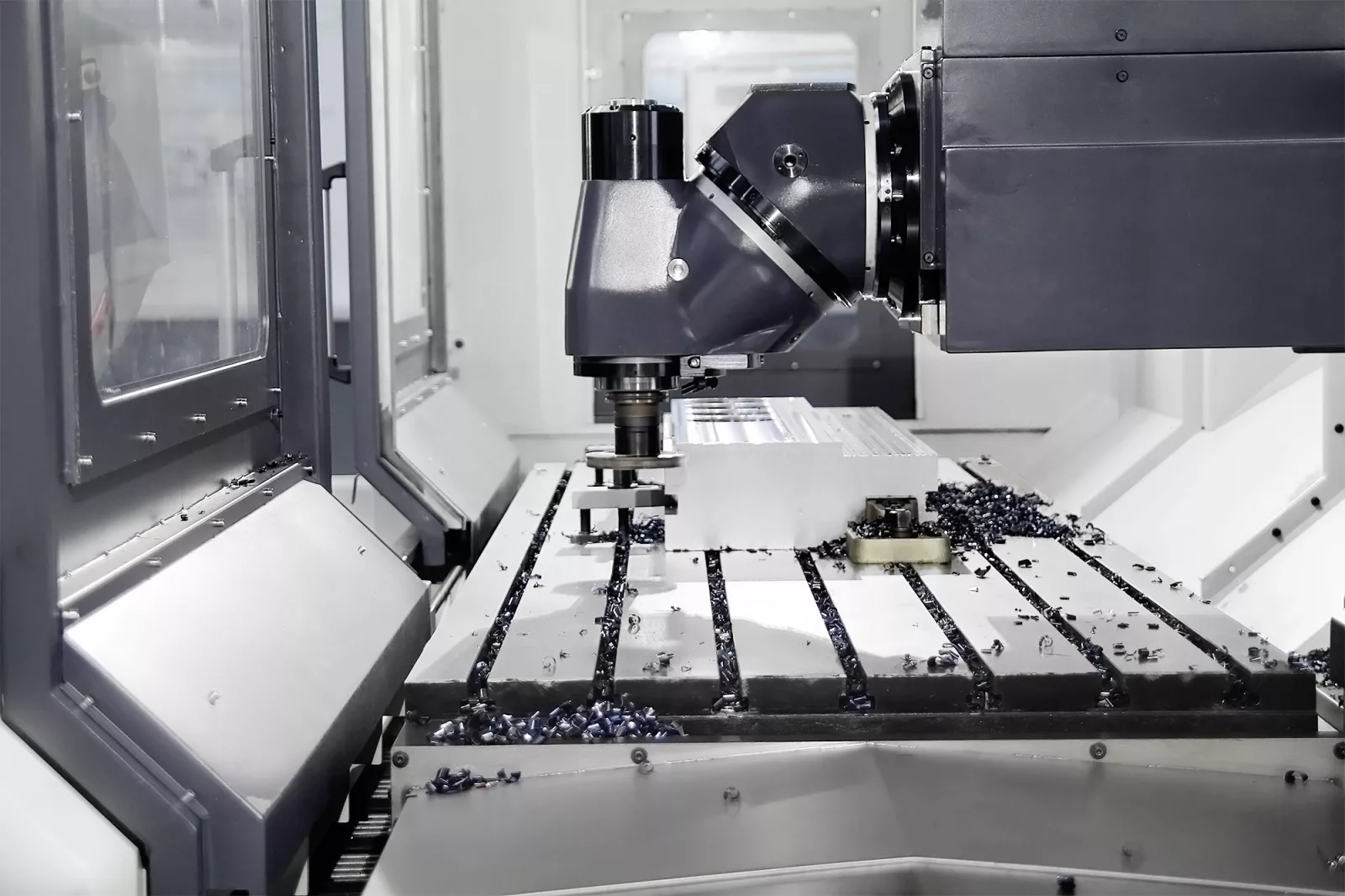

When machining hardened steels, such as nickel-based and titanium alloys, as well as other difficult-to-cut materials, the tools used must meet high requirements. This is because when milling difficult-to-cut materials, it is often necessary to produce an above-average chip volume. In other words, the machines used must be able to withstand much greater process forces than those encountered when machining average structural steel parts. Two operations, one result Heavy-duty machining is usually carried out in two steps. The first step is "roughing". In milling, roughing is a coarse pre-machining of the workpiece for subsequent fine machining. The aim is to remove as much material as possible in the shortest possible time. This step does not produce a precise finished dimension, but only a rough surface. A small amount of material remains on the component. The final step is "finishing", i.e. the completion of the work. To produce the finished dimension, a shallow cutting depth is used. This process also produces a better, finer surface finish.

What are the advantages of heavy-duty machines?

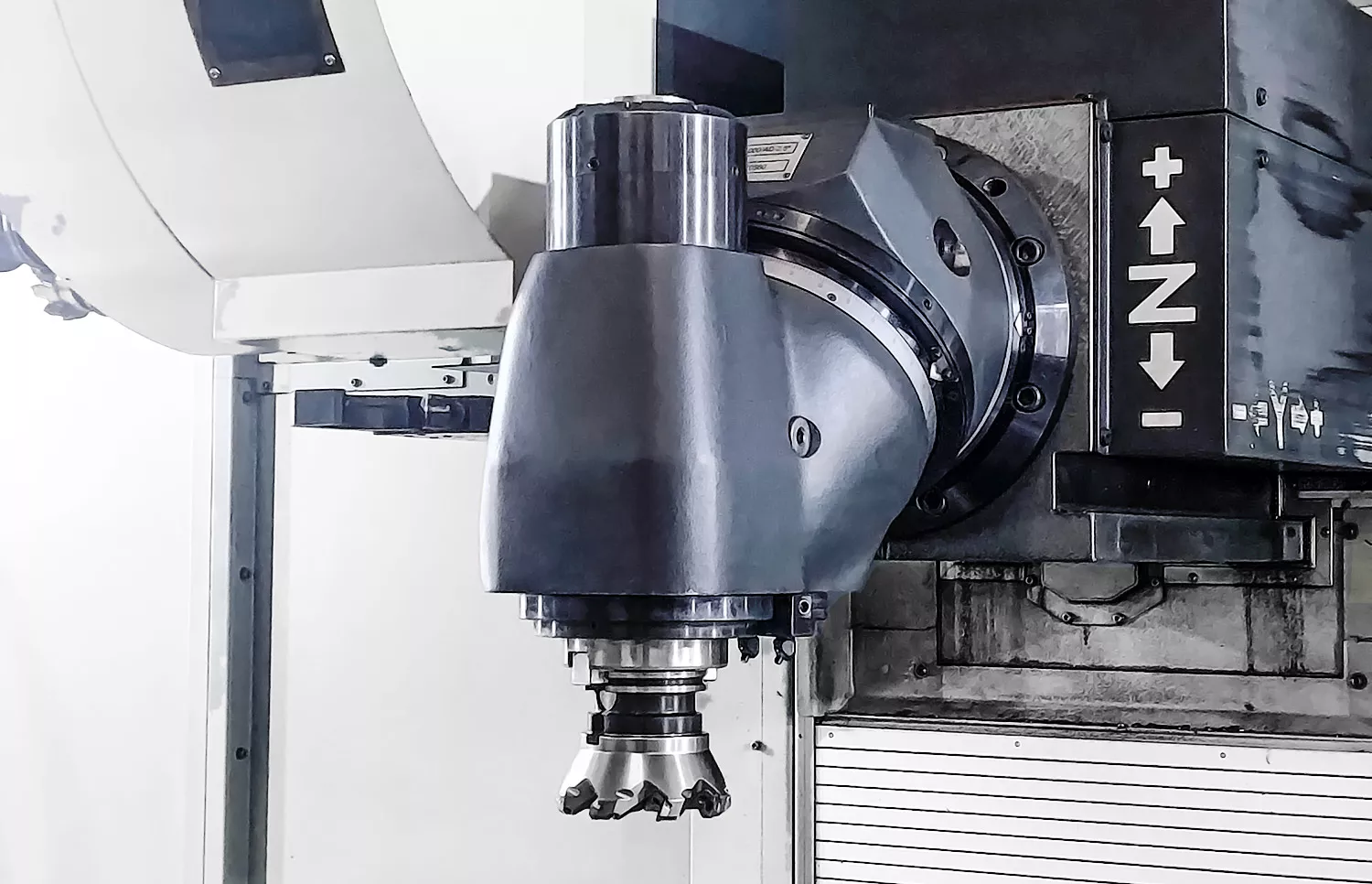

Heavy-duty machining requires machines with a high degree of stability and dynamics, which can only be achieved with a stable basic machine design, ideally made of cast iron and with powerful drives. The two processes, "roughing" and "finishing", can then be carried out by a single machine. This saves additional work steps. For economic reasons, most machines are being built lighter and lighter, with less cast iron being used or even being manufactured from a steel welded construction. Their disadvantage: they are lighter and therefore also less stable. This leads to more vibrations during operation. The result: the service life of the machines is shortened or various processes in the complex field of heavy-duty machining become simply impossible. The higher the vibrations during machining, the greater the wear, both on the machine and on the tool. The exact service life is difficult to quantify, as it depends heavily on the individual care, maintenance and operating mode of the machine.

A trio of success factors

One thing is clear, however: in addition to high stability, heavy-duty machining also requires high damping properties and high drive power. The more stable a machine is, the less vibration occurs during milling. This results in significantly longer tool life. The second guarantee for success is accuracy. Just as important as the stability and accuracy of the machine is its dynamics. Only a dynamic machine can achieve highly accurate finish surfaces.

Digression: MTE has the solution

As a manufacturer, MTE has risen to the challenge. Whether for a bed type milling machine, traveling column milling machine or fixed table travelling column milling machine. All guides are extremely large and are "scraped in" by hand on flat-guided machines. On the linear-guided machines, all reference surfaces of the guides are ground to generate a higher load-bearing surface. In addition, our assemblies, such as the machine table, tower and saddle, are made of cast iron. The service life of a stable machine is therefore considerably longer than that of an unstable machine and thus also more sustainable. A reliable partner

Stability, accuracy, dynamics: MTE's heavy-duty machines make heavy work easier. Just like our employees, who will advise and support you in all matters relating to your MTE. As often and for as long as you need us!

Would you like to learn more about MTE machines? Then continue reading our machine overview. Would you like to get to know the people at MTE better and benefit from their expertise? Then schedule a consultation appointment.