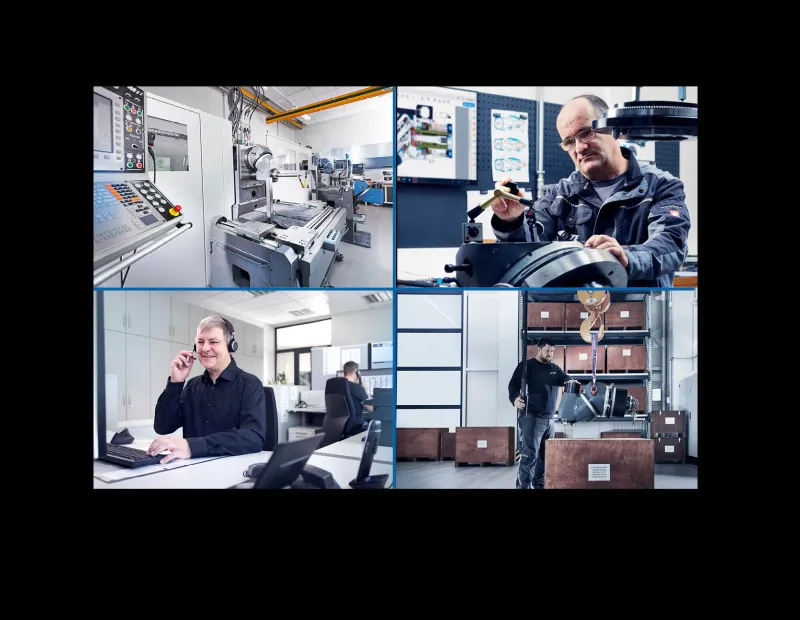

As a manufacturer, milling in-house

At MTE, we consistently focus on a high level of vertical integration: at our factory in Itziar, Spain, we mill our assemblies ourselves – on our own machines and with over 30 years of experience. This strategy not only ensures maximum precision, but also continuous innovation and quality.MTE: The milling machine manufacturer that also mills its own parts

It stands to reason: anyone who manufactures milling machines should machine the assemblies that are installed in their own machines themselves. However, in practice, this is not the case for many machine manufacturers. A shortage of skilled workers, high costs and a lack of expertise have led to fewer and fewer manufacturers producing and machining their own parts. We mill our own assemblies At our plant in Itziar, we machine our assemblies from the raw casting stage onwards – on our own MTE milling machines, of course. We use two large double-column milling machines from the FBF M series, two bed type milling machines from the K & KT series and an RTV rotary table bed type milling machine. The machine park is supplemented by a grinding machine and a boring machine. Our employees have a wealth of experience and expertise, which is particularly important when milling large components. The process: from raw casting to customised production We obtain the cast components in batches from a regional foundry. This means that the castings delivered are usually not yet assigned to a specific project. First, we rough-mill the assemblies and allow for an additional allowance. We then store the assemblies so that any tension in the material can be released while they rest. We then manufacture the assemblies to order and to the required dimensions. We mill large assemblies such as machine beds, machine tables, machine towers or booms at an angle. This allows us to machine the parts in just a few set-ups and ensure optimum chip removal. Some assemblies run over several shifts and days. Our experienced employees know exactly when a drill or milling cutter has reached the end of its service life.

Precision and experience in mechanical engineering

In mechanical engineering, where high precision is required, it is essential to have a thorough understanding of both the machines and the parts to be manufactured. Simply milling according to drawings does not always produce the desired result. With over 30 years of experience, we know which milling strategy and which tool will achieve the required result. Nevertheless, we are constantly learning, as each component behaves differently and requires individual adjustments. Keeping added value in-house A large part of our added value lies in the fact that we carry out many processes ourselves. In addition to milling and grinding, we also build our own milling heads. We are our own guinea pigs When we develop new products, we test them first in our own production. We test and optimise innovations such as new milling heads in our machining department before they go to our customers. This ensures that our machines meet the highest quality standards and are continuously improved.