MTE & EKATO - Large milling machine for large shafts

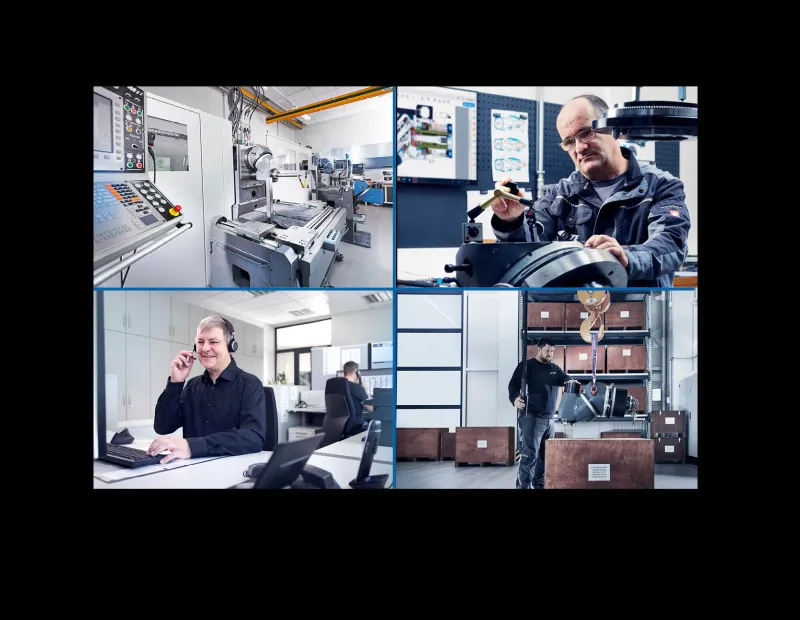

When components exceed the limits of what is feasible, innovative solutions are required. This was the case for mixing and blending technology specialist EKATO in Schopfheim when the production of agitator blades with a diameter of over 10 metres and shafts up to 20 metres long reached its limits. In the following article, we reveal how we solved the problem.When component sizes exceed existing manufacturing capabilities, action must be taken. At EKATO in Schopfheim – a market leader in the field of stirring and mixing technology – this was achieved by replacing the old fixed table travelling column milling machine with a modern floor type milling machine from MTE Deutschland GmbH. Stirring blades with diameters of 10 metres or more and drive powers of several thousand kW are impressive figures and everyday business at EKATO. The shafts for these enormous agitators, which are up to 20 m long and have a diameter of 500 mm, are machined on an MTE FBF-M 6000 floor type milling machine.

The fixed table travelling column milling machine previously used in production was not only getting on in years, but its travel distances no longer met the requirements for the modern machining of large components.

Sascha Madzovski, the employee responsible for production and programming at EKATO, set out to find a suitable replacement and found what he was looking for at MTE. Since a BT 4200 bed type milling machine had already been purchased from MTE the previous year, the company was familiar with its quality and reliability, and the offer was prepared by the responsible sales representative, Wolfram Krieger, according to EKATO's requirements. With travel distances of X = 6,000 mm, vertical Y = 2,500 mm and transverse Z = 1,500 mm, the generous machine enclosure with wide-opening safety doors and a tool magazine with 60 slots, the Floor type milling machine has everything it needs to flexibly machine the long shafts.

In the end, MTE achieved all of the goals that had been set: setup times were significantly reduced and the machining results meet EKATO's desired quality standards!

The successful collaboration between EKATO and MTE has now been ongoing for many years. In addition to the two machines mentioned above, two more have been in production in Schopfheim for some time now: a K 2700-R bed type milling machine with integrated rotary table for highly flexible 5-sided machining of complex smaller components and an SB-M 5500 fixed table travelling column milling machine.