Sustainability and cost efficiency through cooling lubricant maintenance

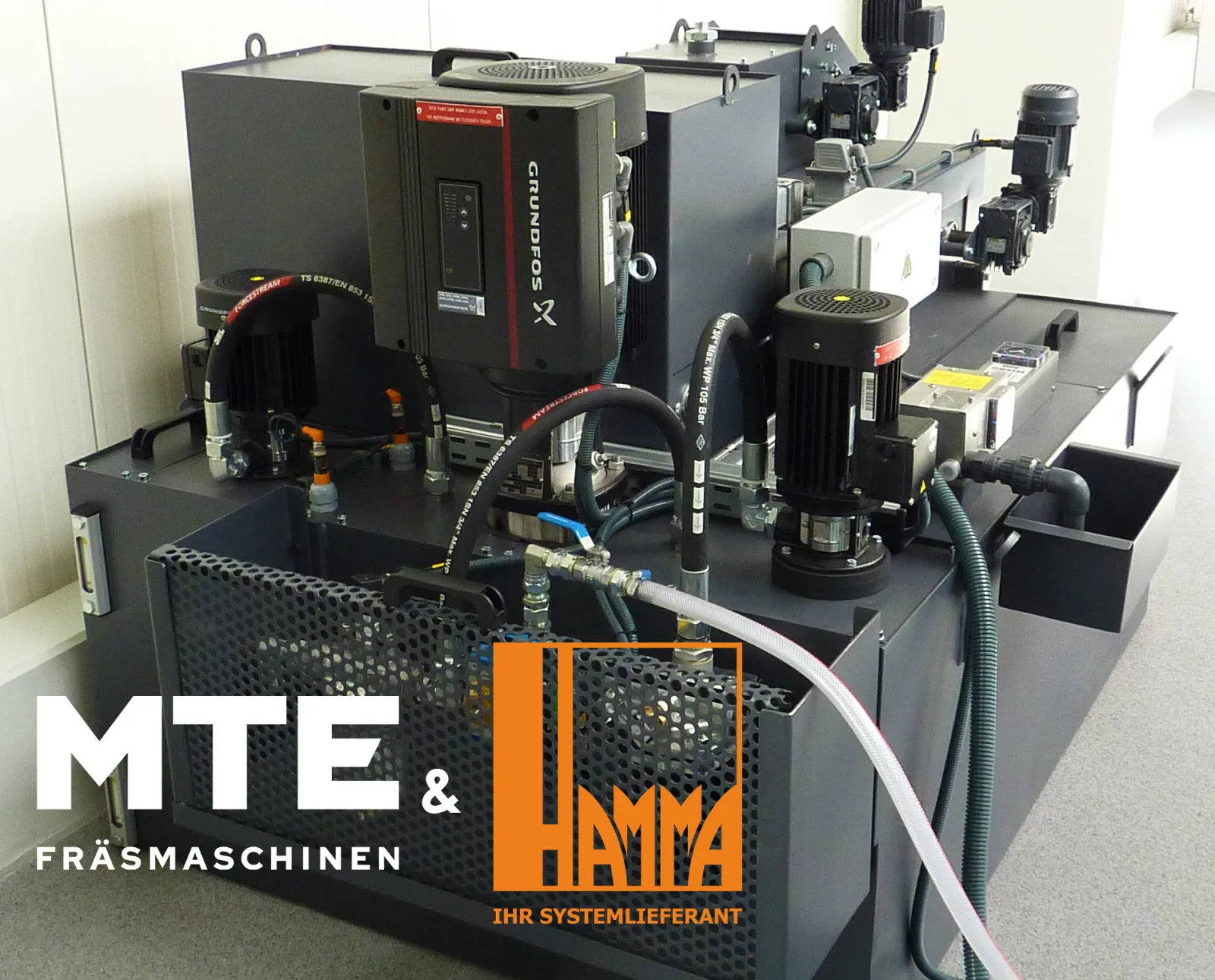

Efficient cooling lubricant maintenance: The successful collaboration between MTE milling machines and Hamma Umwelttechnik.In the metalworking industry, the quality of cooling lubricants plays a decisive role. It influences not only the quality of machining, but also the service life of tools and machines. As a leading manufacturer of milling machines, MTE sets the highest standards – not only in production, but also in the maintenance of cooling lubricants. That is why we work closely with Hamma, a specialist in cooling lubricant maintenance solutions.

Innovative solutions for a clean production environment

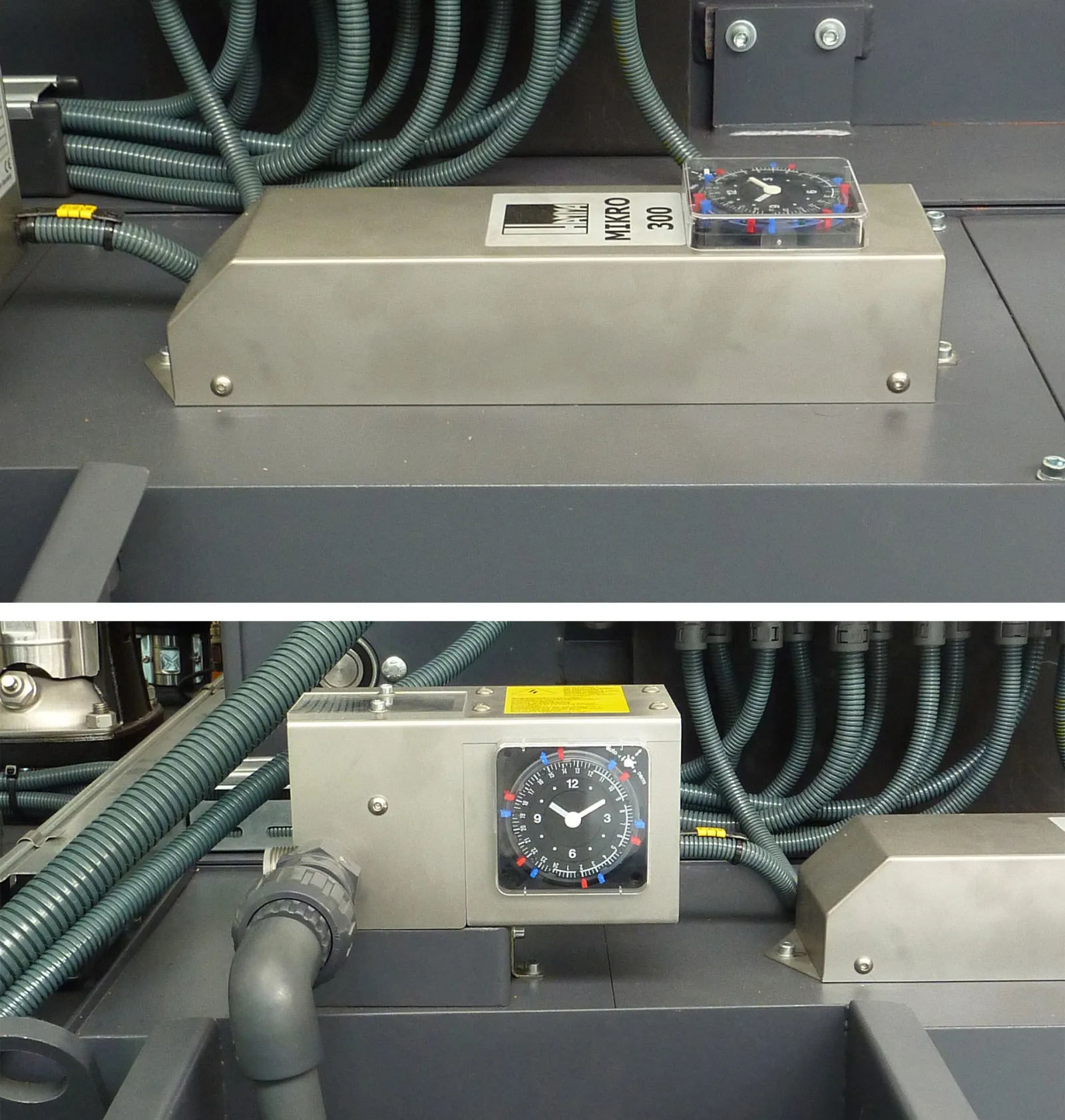

To optimise the efficiency and sustainability of our machines, we use Hamma's proven micro-aerators and oil skimmers in our cooling lubricant tanks. These innovative systems make a significant contribution to improving working conditions and extending the service life of cooling lubricants.

Advantages of micro aerators and oil skimmers

> Micro aerators: These ensure continuous oxygen enrichment of the cooling lubricants, which prevents the formation of bacteria and odours. This maintains the quality of the lubricants for longer and reduces maintenance intervals. Oil belt skimmers: They reliably remove foreign oils from the surface of the cooling lubricant. This not only prevents the formation of oil mist and deposits, but also improves cutting performance and reduces tool wear. Regular maintenance of cooling lubricants helps to keep the production environment clean and efficient. Contaminated or dirty cooling lubricants can not only impair machine performance, but also pose health risks to employees. Through continuous filtration and cleaning using Hamma technology, we ensure that operating conditions remain optimal.

Focus on sustainability and cost efficiency

By using these systems, our customers benefit from longer service life for their cooling lubricants, higher machine availability and lower disposal costs. Our collaboration with Hamma Umwelttechnik enables us to offer sustainable and economical solutions that are not only good for the environment, but also for our customers' budgets. Reducing waste and improving resource utilisation are essential for modern production companies. Lower consumption of cooling lubricants means less refilling and lower operating costs. At the same time, disposal costs are reduced as less waste fluid needs to be disposed of. This is a significant step towards more environmentally friendly and economically sustainable manufacturing.

Long-term partnership for quality and innovation

The close cooperation between MTE and Hamma is based on a shared understanding of quality and innovation. Both companies are committed to forward-looking technologies and continuous development in order to always offer their customers the best solutions. With this partnership, we can ensure that our machines not only work efficiently and precisely, but are also operated in a clean and sustainable environment. Investing in modern cooling lubricant maintenance technologies pays off in the long term – both for the machines and for the entire production chain. MTE uses Hamma systems on all our bed type milling machines, fixed table travelling column milling machines and floor type milling machines. This ensures optimum cooling lubricant maintenance in all our machines and contributes to the efficiency and longevity of our products. MTE and Hamma – a strong partnership for clean, efficient and sustainable manufacturing! wwww.mte.de/maschinen. Details about Hamma Umwelttechnik's cooling lubricant maintenance products can be found at: www.hamma-uwt.de.