Avoid downtime

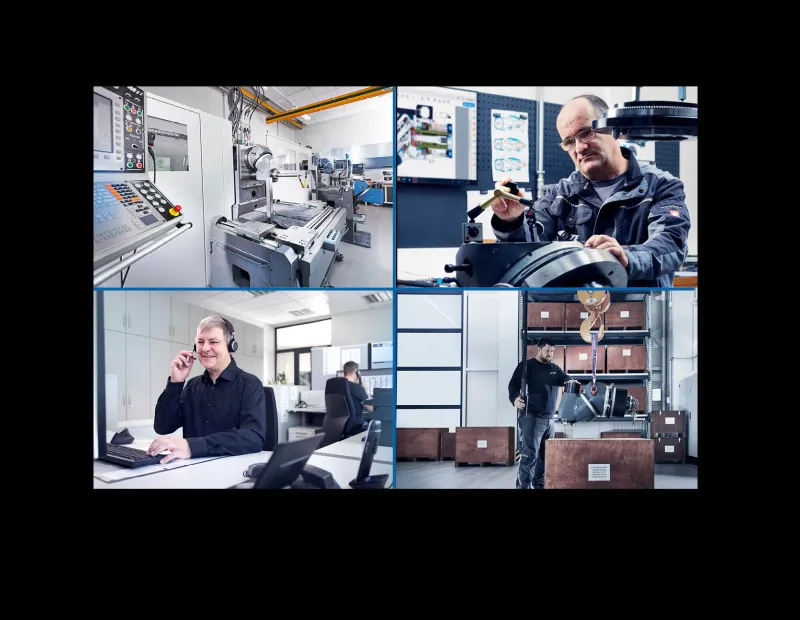

Fixed maintenance intervals ensure the operation of milling machinesThere is no such thing as a machine that does not require maintenance. Mario Bieker is convinced of this. "Only things that are maintained will run for a long time," says the 44-year-old energy systems electronics technician, who has been working at MTE since 2008. As a former field service employee and now a hotline technician for customer service, his responsibilities also include planning maintenance work.

Would you like to learn more about MTE machines? Then read more here.

Regular maintenance on the machines

- Weekly functional checks are carried out, including, for example, checking all door and emergency stop switches, operating materials and fill levels. Another important aspect is the cleaning of various components and equipment. These are all regular tasks that the customer usually carries out themselves. However, Mario Bieker and his service team are happy to provide support with a maintenance plan tailored to the specific machine.

- Every month, the hydraulic and pneumatic pressures and their hoses and fittings are checked. The condition of the fans and their filter mats is also important, as this is the only way to ensure that the cooling circuits work effectively. To avoid malfunctions, the sensors of the tool changer should be cleaned regularly. To ensure that the machine remains as precise as on the first day, it is important to measure the machine kinematics regularly. MTE is also happy to support its customers in this regard.

- Annually Depending on usage, more extensive maintenance may be required. This is where the MTE service fleet comes into play. The technicians change the oil in the hydraulic unit and replace the filters. They also replace the classic wear parts (scrapers, timing belts, etc.). A visual check is carried out to ensure that all electrical components and relays are functioning reliably. The play of each ball screw is measured and adjusted if necessary. The accuracy of the milling machine is also checked. The service includes an inventory of the entire geometry. Finally, a complete functional test is carried out.

Playing it safe with the milling head too

In addition to the machine, the milling head should also be checked regularly to ensure it is in good working order and adjusted if necessary. MTE has set up its own milling head workshop in Montabaur for this purpose. Technicians specially trained and qualified in milling heads repair them quickly, safely and, above all, to the highest standards. After an initial fault analysis at the customer's premises, the milling heads are dismantled in the MTE workshop and examined in detail. Depending on requirements, the technicians replace bevel gears, ball bearings, seals or other parts. The tightness is checked and the geometry of the milling head is measured. A swivel and bearing running-in programme is carried out and a final function test is performed.

In operation around the clock

Downtime must always be avoided. The rental head service offered by MTE provides support when a milling head needs to be thoroughly serviced or repaired. This means that work can continue without interruption. "98 percent of spare parts can be delivered within 24 hours," emphasises Mario Bieker. However, it is best to avoid unforeseen downtime in the first place. This is ensured by the service technicians, who proactively assess during maintenance whether and when a milling head needs to be serviced.

Sharing knowledge

The service staff also pass on their expert knowledge to customers. Mario Bieker offers training courses to enable operating personnel to work better and more safely with MTE. "Like maintenance, training is tailored to the customer's individual needs," says Bieker.

Would you like to find out more about our training courses? Then click here.