In constant exchange

We rely on communication in project managementCommunication is the key to success. This is also the motto we follow at MTE. Communication between the customer and MTE employees is essential, especially in project management. This is the only way we can find out what you need – and build the right bed type milling machine and floor type milling machine for you.

What exactly does your machine need to do? How should it fit into your existing machine park? Which features are essential – what would you like to have as extras? What are the conditions on site – which MTE is the perfect fit? These and other detailed questions need to be clarified at the start of our joint project. To this end, we work in five phases during project implementation.

Not sure if MTE is the right partner for you?

Phase 1: Project discussions

In the first phase, we start by getting an idea of the conditions at your site. After all, we need to know the framework conditions so that your MTE works optimally from day one. To do this, we first measure the site precisely. This allows us to define the necessary connection points. At the same time, this gives us an overview of the preparatory measures that we and you still need to plan. Based on this, we then draw up a schedule and define the specific steps for the day of delivery and installation of your MTE.

Would you like to get a more detailed picture of our repertoire? Then find out more about the machines here:

Phase 2: Layout creation

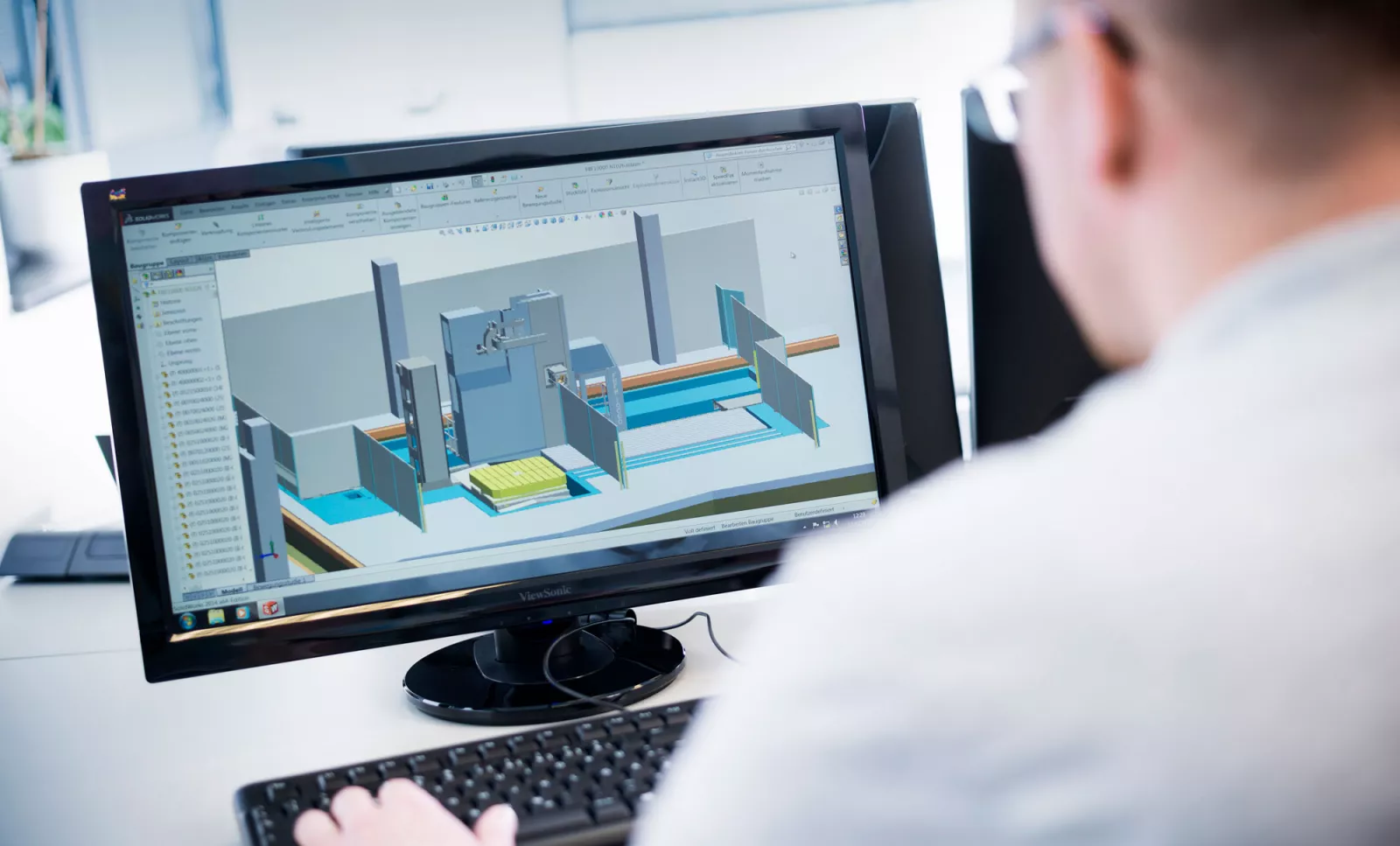

Once we have gathered all the important information during the project discussions, we can move on to the layout phase. Our project manager compares the details obtained with the machine's design data and creates a 2D layout based on this information. You then have the opportunity to review the initial layout. Only when you are satisfied with the design do we produce a realistic 3D representation. This integrates the final installation site with all the relevant conditions. At the same time, we can create the machine layouts and the plans for the foundation, forces and empty conduits.

Phase 3: Foundation discussion

Stability and long-term precision are guarantees of success when working with bed type milling machines and floor type milling machines. The right foundation is crucial. That is why we devote particular care to its planning. After discussing the exact location and the different levels of the foundation with the customer, we create a machine layout tailored to the foundation requirements. This machine layout serves as the basis for the construction company/structural engineer to draw up a formwork and reinforcement plan. During the construction phase, we remain in close contact with the relevant parties in order to provide advice during the execution and to answer any questions. The customer bears ultimate responsibility for the execution of the foundation. Before the machine is delivered, the foundation is checked for dimensional accuracy together with the customer.

Phase 4: Installation

To ensure that everything runs smoothly during installation, we draw up a detailed installation plan with a schedule in advance. Our experienced and well-trained technicians can use this as a guide when installing your MTE on site. The installation process is monitored by the project manager. The installation progress is discussed at regular department head meetings so that we can respond across departments as needed. In addition, the project manager and/or sales representative visit the construction sites at regular intervals or as needed.

Phase 5: Commissioning and final acceptance

Once the machine has been successfully installed at your premises, our employees will carry out the commissioning and final acceptance. This includes, for example, the relevant geometric measurements based on the geometry measurement report, a circularity test and laser measurement of all axes. We usually carry out the latter at the MTE factory. However, depending on the machine type, this can also be done at your premises.

Have we sparked your interest? Do you need project advice? Why not arrange a meeting with us?