The perfect bed type milling machine for ZECK

Top usability: made simple for everyday useThe perfect bed type milling machine for ZECK

The Bavarian machine manufacturer ZECK is based in Scheßlitz in Upper Franconia. It is now optimising its machine park with a new MTE bed type milling machine.

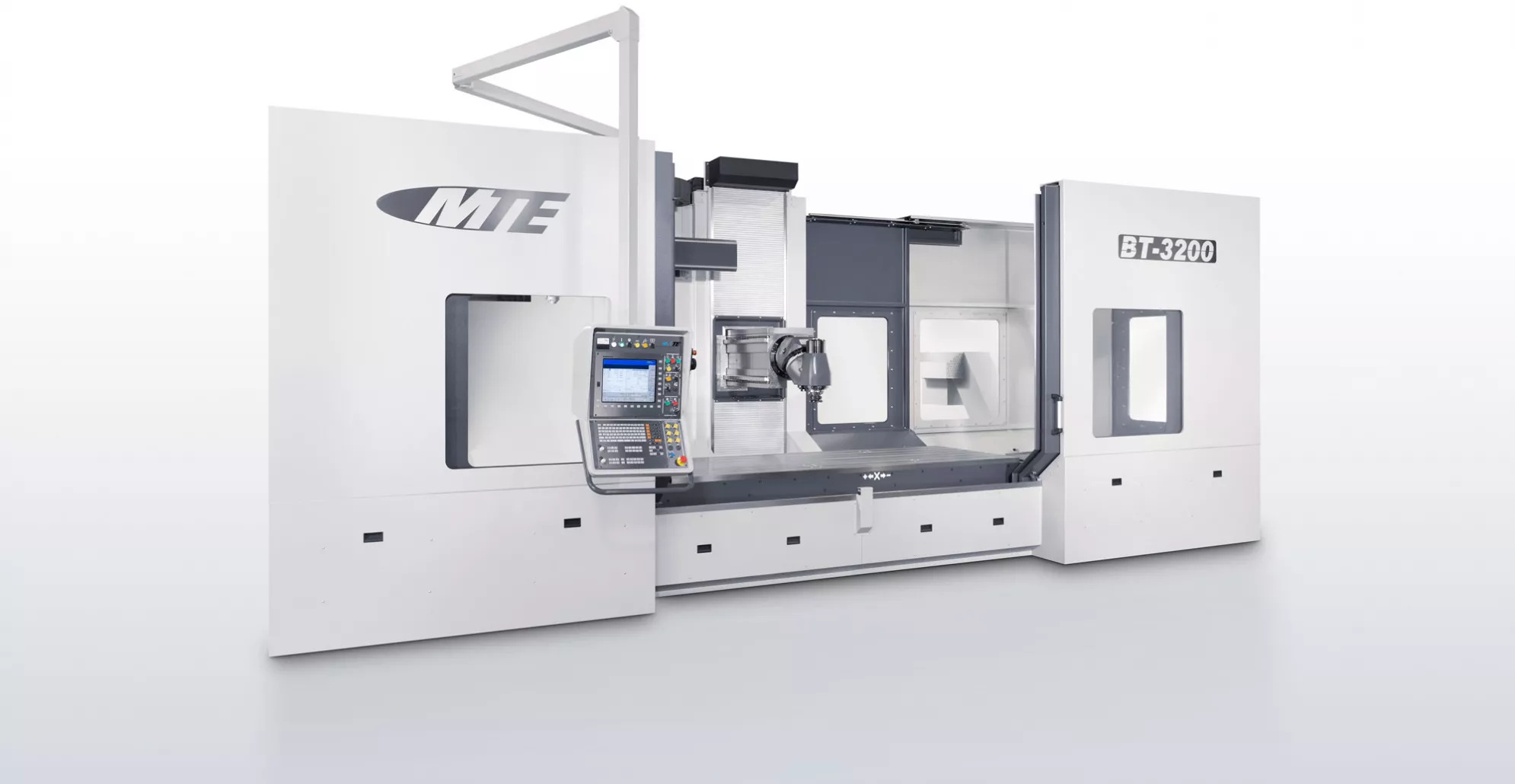

ZECK is more than just a manufacturer from Germany. The company enjoys an excellent reputation worldwide for its high-quality machines. These are used in pipeline construction. ZECK's complex special solutions are particularly renowned in the fields of railway technology, overhead line construction, cable car technology, underground duct technology and antenna construction. We are therefore all the more delighted that the new MTE BT 2700 bed type milling machine is now also in use at this innovative manufacturer in Germany.

Impressive size, lightweight design

The new MTE BT 2700 bed type milling machine has a travel range of 2,500 mm in the X-axis (longitudinal travel) 1,500 mm travel in the Z-axis (vertical travel) and 1,000 mm travel in the Y-axis (transverse travel). The BT 2700 bed type milling machine has a 2,700 mm long and 1,000 mm wide machine table as a clamping surface. This can carry a transport load of 9,000 kg. Another special feature of the BT 2700 is that it has a rear door and two front doors. These can be opened across the entire width of the machine table. This makes it quick and easy to set up and adjust the bed type milling machine.

Just the right flexibility

The BT 2700 bed type milling machine is completed by an automatically indexing milling head. This can be swivelled in two axes in 144 positions at a rate of 2.5° per joint. This ensures the necessary flexibility. The milling head is driven by a powerful 32 kW motor from Heidenhain. This and the 3-stage gearbox give the milling head of the bed type milling machine a maximum torque of 1,520 Nm.

Maximum stability

Like all MTE bed type milling machines , the BT 2700 is characterised by its high stability and accuracy. The solid construction of the milling centre not only ensures high accuracy but also above-average chip volume during drilling and milling. Further highlights include the automatic tool changer on the BT 2700 and the frequency-controlled cooling lubricant system.

Top operability: made easy for everyday use

We have equipped the machine's control panel with a Heidenhain TNC 640 CNC control. A particularly practical feature is that this panel can be swivelled directly through the bed type milling machine. This means that the operator can easily program and work in front of or behind the machine table. In addition, an M & H Hexagon radio measuring probe system is part of the design. This allows the workpieces, which change daily, to be measured quickly and accurately. This is crucial because ZECK manufactures a wide variety of assemblies on the machine every day, which also have to meet a high set of requirements. The machine concept is rounded off by all-round cladding and a total of three chip conveyors in front of and behind the machine table. These ensure clean and efficient working.

For Christian Friedrich, a long-standing ZECK employee responsible for work preparation and production planning at the company, high quality, stability and precision were not the only important factors when awarding the contract. It was particularly important to him that reliable service was always available in case of an emergency. Our service structures and spare parts warehouse in Montabaur were decisive factors in the decision to choose MTE bed type milling machines. We look forward to a long and successful partnership with this renowned manufacturer from Germany!