When flexibility is key – our BT 3200 in mechanical manufacturing.

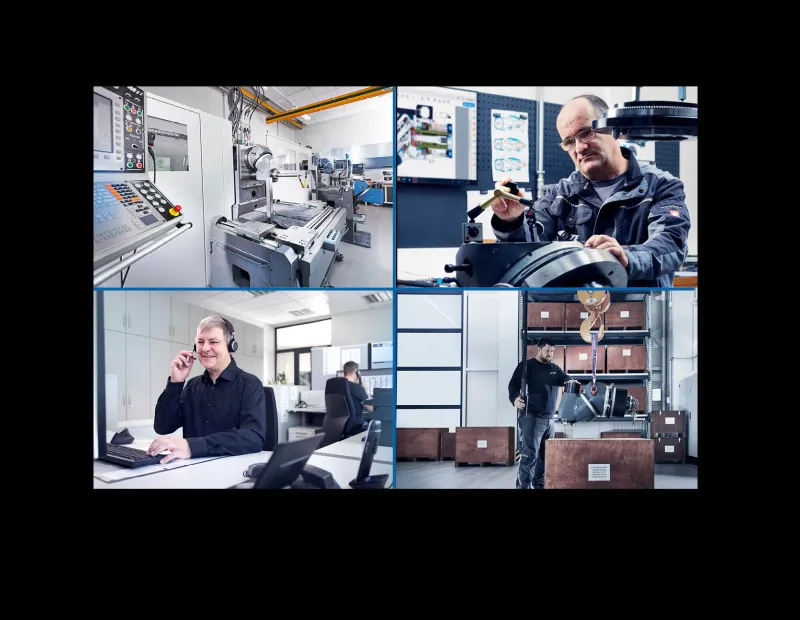

NEUMAN & ESSER has been using an MTE BT 3200 bed type milling machine in its mechanical production since 2017. During this time, the machine has developed into a true all-rounder. From connecting rods to crossheads, cylinder covers and pistons, almost everything runs on the BT 3200.In the repair business, as in spare parts manufacturing, the flexibility of the machine pays off. "Restoring shape and position, i.e. levelling, manufacturing everything from standard covers to smaller cylinders, large connecting rods and much more – in the milling area, we can reliably machine the widest variety of parts, both cast and steel, with the BT 3.200," says Simon Prell from the production management team at NEUMAN & ESSER.

The almost 200-year-old family-owned company supplies solutions for tomorrow's energy infrastructure, from state-of-the-art compressors and grinding and screening systems to electrolysers and hydrogen filling stations. In its mechanical production facility in Übach-Palenberg, NEUMAN & ESSER relies on the particularly flexible BT 3.200 bed type milling machine from MTE. Looking back, the production manager cannot think of a single instance to date where the machine has reached the limits of its machining capabilities.

Universally applicable – the BT 3.200 with rotary table

Due to the high level of vertical integration – everything is produced in-house, from M12 expansion bolts to 6-metre crankshafts and from 12-tonne cylinders to 50-tonne crankcases – mechanical production must be particularly flexible when it comes to spare parts and repairs. The rotary table also gives the company the option of producing a large number of components in a single setup."

"There is no other milling machine on which we can produce such a wide variety of components." Simon Prell from NEUMAN & ESSER

For NEUMAN & ESSER, the solution package clearly also includes service, both during commissioning and after several years of operation. Overall, his company has come to appreciate the support provided by MTE over the past six years, summarises Simon Prell. "Our own milling head workshop at the Montabaur site, trained technicians, our own test bench, spare parts warehouse, loan heads with express service – the package simply has to be right. MTE perhaps ticks in much the same way as we do. Neither of us are product sellers, but solution providers." Praise that we gladly accept.

MTE BT 3.200 bed type milling machine at a glance

- Travel distances: X: 3,000 mm | Y: 1,200 mm | Z: 1,500 mm

- Highest precision with backlash-free INA linear guides in all axes

- Milling head with 2.5°x1° Hirth toothing and 4,000 rpm

- Rotary table 800x800 mm mounted

- Automatic tool changer with 40 magazine slots